Vol. 40 (Number 27) Year 2019. Page 19

UMYSHEV, Dias R. 1; DYUSSEMBEKOVA, Nassipkul K. 2; ZHUMATOVA, Assel A. 3 & MINAZHOVA, Saulesh A. 4

Received: 08/04/2019 • Approved: 03/08/2019 • Published 05/08/2019

ABSTRACT: This article analyzes the possibility of using solar energy in the Republic of Kazakhstan, in particular with the use of heat engines. Numerous studies show that the application of heat engines in combination with solar energy makes it possible to obtain a sufficiently large amount of electrical energy, but the development of additional thermal energy makes it possible to speak about quite high rates, since the combined generation of thermal and electrical energy increases the cycle efficiency. |

RESUMEN: Este artículo analiza la posibilidad de utilizar energía solar en la República de Kazajstán, en particular con el uso de motores térmicos. Numerosos estudios muestran que la aplicación de motores térmicos en combinación con energía solar permite obtener una cantidad de energía eléctrica suficientemente grande, pero el desarrollo de energía térmica adicional permite hablar de tasas bastante altas, ya que la generación combinada de energía térmica. Y la energía eléctrica aumenta la eficiencia del ciclo. |

Electrical and thermal energy is key to the humanity. 87.8% of the electricity is generated at TPPs, where fossil fuel is the source of energy. Unfortunately, fossil fuels are limited. RES allows saving fossil fuels and reducing the burden on the environment.

Solar energy reaches the surface of the earth in the form of sunrays, which can be disposed of in two ways: the first is solar collectors for producing thermal energy, the second is the photoelectric method. The global potential for power generation using the second method reaches 227 GW, thermal energy 435 GW.

Solar energy reaching the surface is 105 thousand TW. If you take only 1% of the energy coming to the surface with an efficiency of 10%, you can get energy in the amount of 105 TW. Given the global growth in electricity demand of 25-30 TW by 2050, the demand for Kazakhstan is 20,000 MW, the solar energy has great potential.

In the field of solar power there are several approaches to the utilization of solar energy. Photovoltaic concentrators have an efficiency of 40%, solar panels 20%, and solar thermal systems provide an efficiency of 40-60%.

Particularly interesting is the use of solar generators in combination with heat engines for several reasons:

1. Heat engines are the most widely used engine types, therefore they are easier to implement;

2. They have a high energy conversion rate, at least for the present;

3. High efficiency in the range of 30-40% (in particular Stirling engines).

Based on the analysis performed, it can be concluded that the most effective solution for the use of renewable energy sources is the use of Stirling heat engines for energy conversion.

The main factors that paid great attention to the development of the system were the reliability, performance and cost of the system. Therefore, most of researches have paid attention to the modeling of solar dish based on Stirling engines, to the optimization of high-temperature heat receiver, to the optimization of the design of Ferreira, to the geometric properties of the cavity of the receiver. In other studies, attention was paid to various resonator receiver configurations that increased heat transfer and reduced heat loss, such as the hemispheric receiver by Tan and Reddy, a cylindrical receiver by Mao and Madadi Avargani, rectangular by Loni and Spiral coil absorber by Pavlovic’. Studies have also been conducted on the possibility of using Stirling solar battery systems in various places and in different climatic conditions. Reducing the cost of a solar concentrator was taken into account in the literature, which were further evaluated by Bakos.

Despite a number of significant advantages of Stirling engines, they have not yet received noticeable mass distribution. This is due to a number of circumstances, such as technical and economic as well as commercial. However, they are becoming increasingly popular in the leading Western countries.

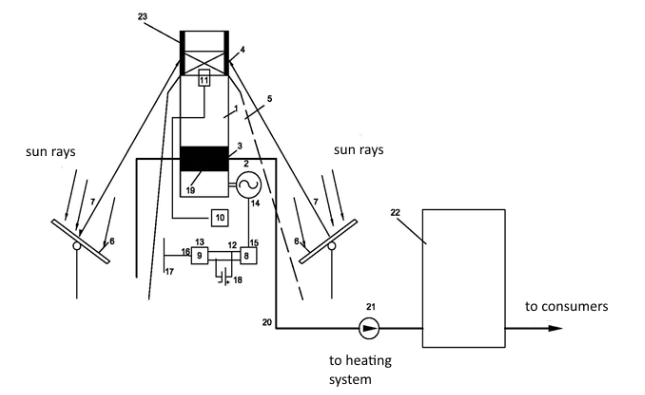

The authors have developed the following devices presented in Figures 1 and 2.

Figure 1

Solar generator based

on Stirling engine

Elaboration: own

The figure shows a tower solar generator. The solar generator with a Stirling engine works as follows: in a sunny weather, the sunrays hit the mirrors with sunray reflectors, the reflected rays get into the heater 4 that is equipped with heat pipes that allow to conduct the heat that drives the Stirling engine more efficiently, a cooling system with water-gas heat exchanger cools the internal cycle gas of a Stirling engine, transfers the hot gas through the heat exchanger to the hot water found in the hot water pipes, which is transported by the circulating pump to a storage tank where it can stack and be dispensed to the consumers of hot water. The mechanical energy of the Stirling engine is transmitted to the electric generator, which transmits electricity to consumers. With an excess of electricity, it accumulates in the battery.

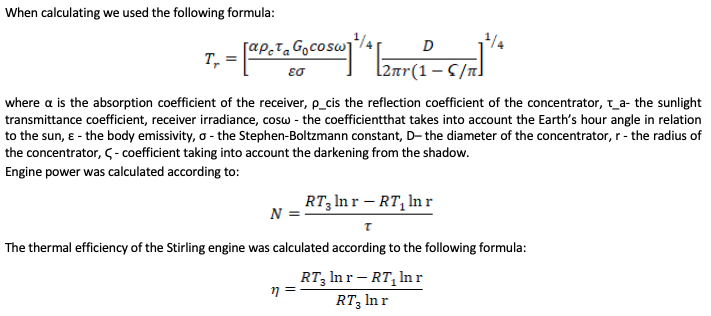

Figure 2

Autonomous solar generator

based on the Stirling engine

Elaboration: own

Figure 2 shows an autonomous solar generator based on a Stirling engine. The sun rays that hit the reflecting surface of the receiving plate are reflected into the focus in which the Stirling engine 5 is installed, where the temperature, depending on the size of the plate, can reach 500 0С. The sun rays hitting the heat receiver with heat pipes 6 heat the gas in the Stirling engine 5, which activates the engine. The mechanical energy of the piston movement is converted into the electrical energy by means of an electric generator, which feeds the circulating pump and transfers electricity to consumers through electric cables in the bracket. In order to cool the hot gases in the Stirling engine, a heat exchange system consisting of a heat exchanger with inlet and outlet tubes is provided. The water enters the Stirling engine through the incoming tubes, the pressure of which is created by the circulating pump, after heating the water through the outgoing tubes enters the storage tank. In cases where there is no need for hot water, a valve is installed between the circulating pump and the storage tank, when closed water will not flow into the cooling circuit and the heat exchanger. In this case, the efficiency of the power plant in the proposed invention will be lower.

The following assumptions were used in the calculation:

where R is the air gas constant, T3, T1 are the temperatures of the hot and cold source, r – Vmax / Vmin is the ratio of volumes in the working process.

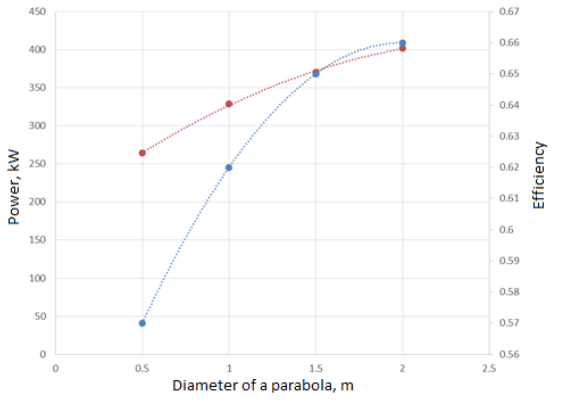

Figure 3

Dependence of power and efficiency

on the diameter of the solar parabola

Figure 3 shows the dependence of power and efficiency on the diameter of the solar parabola. When calculating it was assumed that solar radiation for all cases is equal to 500 W / m2. It is obvious that the increase in the diameter of the solar collector in the form of a parabola increases the heating of the heat receiver of the Stirling engine (SE). As can be seen from the figure, a significant increase in the efficiency is observed with a diameter of 1.5 m. A further increase in diameter leads to a slight increase in efficiency of 1.5% compared with an increase from 1 to 1.5 m, where the increase is 6%. Possibly this change occurs due to the fact that at these temperatures the air has the optimal values of heat capacities.

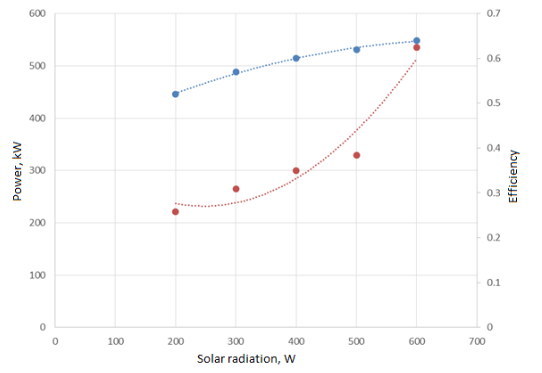

Figure 4

Dependence of power and

efficiency on the solar radiation

Figure 4 shows the dependence of the Stirling engine power on solar radiation, with a solar collector diameter of 1 m and a constant temperature of the cold part of 300 K. As can be seen from the figure, an increase in solar radiation leads to an increase in power, but a significant increase falls on the value of 600 K. However, the efficiency of the system in principle is not strictly dependent on the solar radiation.

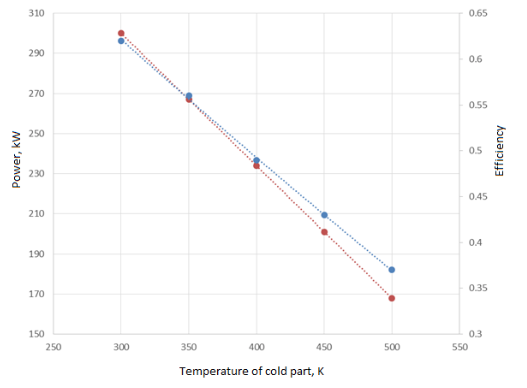

Figure 5

The dependence of power and efficiency

on the temperature of the cold part

Figure 5 shows the dependence of power and efficiency of the Stirling engine on the temperature of the cold part. When calculating, it was assumed that the diameter of the solar collector is 1 m,the solar radiation is 500 W / m2. It is obvious that the efficiency of a heat engine largely depends on the temperature at the hot and cold “end” of the heat engine. The data presented shows that with decreasing temperature differences power and efficiency fall, having the same character as well.

Calculations show that the efficiency of an ideal Stirling cycle can reach 60%. However, in real cycles this figure will be lower, due to the leakage of the coolant, the friction of various parts, temperature gradients, the heat loss on heating of metal surfaces, etc. The authors believe that, while reducing the efficiency to 40-45%, the attractiveness of the proposed solution to use Stirling engines together with solar collectors will not decrease.

The maximum values of efficiency and power were obtained when the diameter of the solar collector was 2 m, and they were equal to 0.66, 402 kW, respectively. However, given the relatively high efficiency, with technical implementation it is possible to use diameters of 1-1.5 m.

The analysis shows that the size of the solar collectors and the temperature in the cold area largely influence the efficiency of the engines. The first issue is solved by installing large collectors. The second issue can be resolved by installing heat exchangers for the heating system.

Abbas M., Boumeddane B., Said N., Chikouche A. (2015). Techno economic study of the utilization of solar dish stirling technology for electricity generation at the Algerian Sahara. Energy Source Part A: Recov Util Environ Effects, 1400–1409.

Bakos G.C., Antoniades Ch. (2013). Techno-economic appraisal of a dish/Stirling solar power plant in Greece based on an innovative solar concentrator formed by elastic film. Renew Energy, 60, 46–53.

Boukelia T.E., Mecibah M.S., Kumar B.N., Reddy K.S. (2015). Optimization, selection and feasibility study of solar parabolic trough power plants for Algerian conditions. Energy Convers Manage, 101, 450–459.

Ferreira A.C., Teixeira S., Teixeira J.C., Martins L.B. (2015). Design optimization of a solar dish collector for its application with stirling engines. In: ASME 2015 international mechanical engineering congress and exposition, volume 6A, 13–19.

Hijazi H., Mokhiamar O., Elsamni O. (2016). Mechanical design of a low cost parabolic solar dish concentrator. Alexandria Eng J, 55(1), 1–11.

Hosseinzade H., Sayyaadi H. (2015). CAFS: The combined adiabatic-finite speed thermal model for simulation and optimization of Stirling engines. Energy Convers Manage, 91, 32–53.

Hussain T., Islam M.D., Kubo I., Watanabe T. (2016). Study of heat transfer through a cavity receiver for a solar powered advanced Stirling engine generator. ApplThermEng, 104, 751–757.

Kalogirou S. (2014). Solar energy engineering: processes and systems. Academic Press, 2nd ed., 840 p.

Li H., Huang W., Huang F., Hub P., Chen Z. (2013). Optical analysis and optimization of parabolic dish solar concentrator with a cavity receiver. Sol Energy, 92, 88–97.

Li Sha, Xu Guoqiang, Luo Xiang, QuanYongkai, GeYunting. (2016). Optical performance of a solar dish concentrator/receiver system: Influence of geometrical and surface properties of cavity receiver. Energy, 113, 95–107.

Loni R., Kasaeian A.B., Askari Asli-Ardeh E., Ghobadian B., Le Roux W.G. (2016). Performance study of a solar-assisted organic Rankine cycle using a dishmounted rectangular-cavity tubular solar receiver. ApplThermEng, 108, 298–309.

Madadi A.V., Rahimi A., Tavakoli T. (2016). Exergetic optimization and optimum operation of a solar dish collector with a cylindrical receiver. EnergyEngJ, 142, 150-163.

Mao Q., Shuai Y., Yuan Y. (2014) Study on radiation flux of the receiver with a parabolic solar concentrator system. Energy Convers Manage, 84, 1–6.

Minazhova S.A., Dostiyarov A.M., Umyshev D.R., Dyussembekova N.K., Zhumatova A.A. (2018) e.a. Solnechniy generator s dvigatelem Stirlinga [Solar generator based on Stirling engine] Patent RK, positive decision on granting with outgoing no.42049, November 16.

Minazhova S.A.,Dostiyarov A.M., Umyshev D.R., Dyussembekova N.K., Zhumatova A.A. (2018). e.a. Avtonomniy solnechniy generator s dvigatelem Stirlinga [Autonomous solar generator based on Stirling engine] Patent RK, application no. 2018/0609.1

Pavlovic´ S.R., Bellos E.A., Stefanovic´ V.P., Tzivanidis Ch., Stamenkovic´ T.Y., Zhao Li, Bao J., Liu Qing. (2014). Experimental investigation on heat loss of semi-spherical cavity receiver. Energy Convers Manage, 87, 76–83.

Przenzak E., Szubel M., Filipowicz M. (2016). The numerical model of the high temperature receiver for concentrated solar radiation. Energy Convers Manage, 125, 97–106.

Reddy K.S., Natarajan S.K., Veershetty G. (2015). Experimental performance investigation of modified cavity receiver with fuzzy focal solar dish concentrator. Renew Energy, 74, 48–57.

Twidell J., Ware A. (1990). Renewable Energy: Trans. from English. Energoatomizdat, 352 p.

Walker G. (1978). Stirling Machines: Trans. from English. Energy, 152 p.

World Energy Scenarios Composing energy futures to 2050. (2013). World Energy Council, London, United Kingdom.

Zoran M. (2016). Design, simulation and optimization of a solar dish collector with spiral-coil thermal absorber. ThermSci, 104, First Issue 00.

1. PhD, Senior lecturer at Power Engineering Department, Satbayev University, Almaty, Kazakhstan, email: umishev_d@mail.ru

2. PhD, Professor at Power Engineering Department, Satbayev University, Almaty, Kazakhstan, email: nassipkuldyussembekova@gmail.com

3. Candidate of Technical Science, Lecturer at Power Engineering Department, Satbayev University, Almaty, Kazakhstan, email: asselzh81@mail.ru

4. Master of Technical Science, Tutor at Power Engineering Department, Satbayev University, Almaty, Kazakhstan, email: s.minazhova@gmail.com