Vol. 39 (Number 32) Year 2018 • Page 20

Celso RECALDE 1; Rafael CORDOVA 2; John CEVALLOS 3; Roberto ARIAS 4; Denys LOPEZ 5; Luz PAUCAR 6; Mario PEREZ 7

Received: 21/02/2018 • Approved: 15/04/2018

ABSTRACT: A plancha stove has been compared to a traditional “grill” stove, additionally the change of room temperature in both kitchens was measured. Only the thermal efficiency of the plancha stove was higher than the one of the grill (p<0.10). The total cooking time was 41% longer for the plancha stove; however, the total mass of meals cooked was 17% greater for the plancha (p<0.10). The safety assessment ranked the plancha and grill stoves into tier 2 and 0 respectively. |

RESUMEN: Se ha comparado una estufa a plancha con una estufa tradicional de "parrilla". Solo la eficiencia térmica de la plancha fue superior a la de la parrilla (p <0,10). El tiempo de cocción total fue 41% más largo para la estufa a la plancha; sin embargo, la masa total de comidas cocinadas fue un 17% mayor para la plancha (p <0,10) respectivamente. La evaluación de seguridad clasificó las estufas de plancha y parrilla en el nivel 2 y 0 respectivamente. |

About half of the world’s population, still rely heavily in the use of biomass for satisfying their energy needs; mainly for cooking and heating(Vaccari, Vitali, & Mazzù, 2012)(Obi, Ezeoha, & Okorie, 2016)(Arora, Jain, & Sachdeva, 2014). Several stove assessments have been conducted for characterizing wood-burning cookstoves using mainly laboratory surveys; however, there have been few studies in-situ on the performance of woodstoves, almost all of these reports conclude that in-field assessments are necessary for observing the real performance of cookstoves(N. MacCarty, Still, & Ogle, 2010)(Lask et al., 2015)(Smith et al., 2007). Aditionally, most of fire-related deaths occur within low and middle income countries(Gallagher, Beard, Clifford, & Watson, 2016). The plancha stove is among the initiatives of improved cooking and quality of life for families in developing countries; it has recently been promoted in Ecuador; however, according to the literature, there is no statistical difference between the efficiency of plancha stoves and open fires(McCracken & Smith, 1998). For the reasons stated before, four standard tests were performed on a plancha stove and on a traditional stove; all the tests were performed in-situ; it should be recognized that performance in the field under varied climatic conditions may be different than performance in the laboratory or predicted by any model; they will be real functioning data(N. A. MacCarty & Bryden, 2015).

In this research paper, a plancha stove has been compared to a traditional “grill” stove using four tests. The protocols followed corresponded to the four tests carried out, namely the water boiling test (WBT 4.2.3), the biomass stove safety protocol (BSSP 1.0), the controlled cooking test (CCT 2.0) and the kitchen performance test (KPT 2.0) for studying the behavior of both the stoves. All tests were performed in Pucará, an Ecuadorean indigenous community located at 3106 m.a.s.l. Local available eucalyptus fuelwood was used. The thermal measurement was done using three thermohigrometers and an infrared thermometer. Figures 1 and 2, show the tested woodstoves.

Figure 1

Plancha stove

-----

Figure 2

Traditional "grill" stove

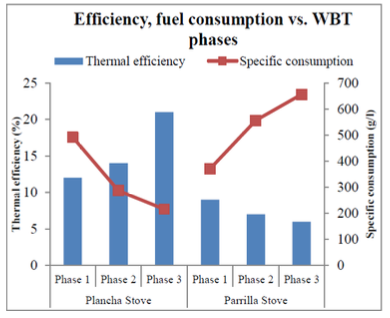

Another research work, where plancha stoves were studied under the same standards, it was concluded that efficiencies of the open fire are higher than the ones of the plancha stove in all the tests’s phases(McCracken & Smith, 1998). In this research project, we encourage a redesign of the plancha stove to improve performance metrics, however, the thermal efficiency was higher for the plancha stove in all the test’s phases. The effect of altitude on combustion also plays a major role in these results, showed in figure 3.

Figure 3

WBT Results

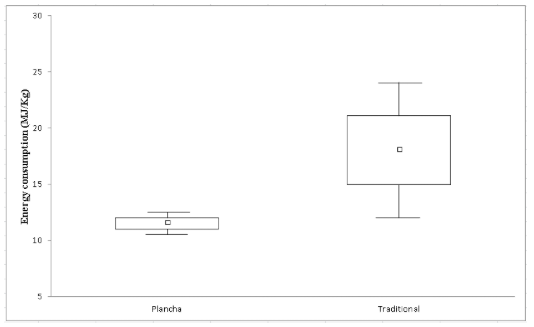

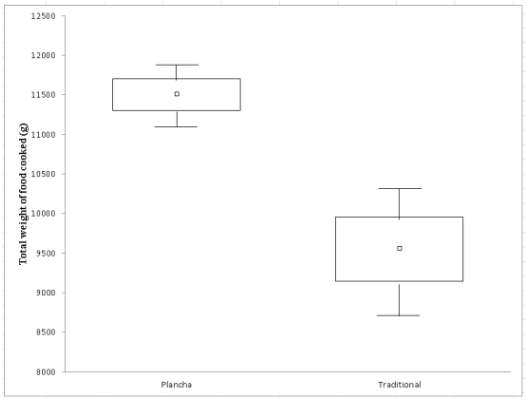

The recipe used for the controlled cooking test was a local common meal that required several cooking tasks. The results showed no significant difference between the two wookstoves, however, the weight of meals from the plancha stove was significantly higher than from the grill (p<0.10) as shown in figures 4 and 5. The total cooking time was 41% longer for the plancha stove; however, the total mass of meals cooked was 17% greater for the plancha (p<0.10).

A kitchen performance test was performed over three days between two households with similar economic status and number of inhabitants. The results from Table 1 show no significant difference between the woodstoves (p<0.10); however, plancha stove users reported few or no smoke into the kitchen.

Figure 4

Energy consumption during the cooking tasks

-----

Figure 5

Total weight of cooked meals

-----

Table 1

Results comparison between the plancha and grill houselholds

Results comparison |

%difference |

Significant 90% of confidence |

No. Of adult equivalents |

-46% |

NO |

Wet wood per cap |

-27% |

NO |

Energy per cap. (MJ/cap) |

-27% |

NO |

Even when the average room temperatures are in a comfortable range, plancha’s surface temperature was over 250 ºC which diminishes its safety. The safety assessment ranked the plancha and grill stoves into tier 2 and 0 respectively.

Thermal efficiency for the plancha stove was higher than that of the grill, in contrast with the results of other research works. The data obtained in this report are actual operating data obtained through in-situ tests, dealing with ambient and combustion issues. There are significant differences in cooking time (longer for plancha stove) and in the mass of cooked food (larger for plancha stove).

This research work was supported by the Climate and Development Foundation CDF, Fondo Ecuatoriano Populorum Progreso. It would not have been done without the support of the researchers from GEAA-ESPOCH.

Arora, P., Jain, S., & Sachdeva, K. (2014). Laboratory based assessment of cookstove performance using energy and emission parameters for North Indian cooking cycle. Biomass and Bioenergy, 69, 211–221. https://doi.org/10.1016/J.BIOMBIOE.2014.07.012

Gallagher, M., Beard, M., Clifford, M. J., & Watson, M. C. (2016). An evaluation of a biomass stove safety protocol used for testing household cookstoves, in low and middle-income countries. Energy for Sustainable Development, 33, 14–25. https://doi.org/10.1016/J.ESD.2016.03.008

Lask, K., Booker, K., Han, T., Granderson, J., Yang, N., Ceballos, C., & Gadgil, A. (2015). Performance comparison of charcoal cookstoves for Haiti: Laboratory testing with Water Boiling and Controlled Cooking Tests. Energy for Sustainable Development, 26, 79–86. https://doi.org/10.1016/J.ESD.2015.02.002

MacCarty, N. A., & Bryden, K. M. (2015). Modeling of household biomass cookstoves: A review. Energy for Sustainable Development, 26, 1–13. https://doi.org/10.1016/J.ESD.2015.02.001

MacCarty, N., Still, D., & Ogle, D. (2010). Fuel use and emissions performance of fifty cooking stoves in the laboratory and related benchmarks of performance. Energy for Sustainable Development, 14(3), 161–171. https://doi.org/10.1016/J.ESD.2010.06.002

McCracken, J. P., & Smith, K. R. (1998). Emissions and efficiency of improved woodburning cookstoves in Highland Gatemala. Environment International, 24(7), 739–747. https://doi.org/10.1016/S0160-4120(98)00062-2

Obi, O. F., Ezeoha, S. L., & Okorie, I. C. (2016). Energetic performance of a top-lit updraft (TLUD) cookstove. Renewable Energy, 99, 730–737. https://doi.org/10.1016/J.RENENE.2016.07.060

Smith, K. R., Dutta, K., Chengappa, C., Gusain, P. P. S., Berrueta, O. M. and V., Edwards, R., … Shields, K. N. (2007). Monitoring and evaluation of improved biomass cookstove programs for indoor air quality and stove performance: conclusions from the Household Energy and Health Project. Energy for Sustainable Development, 11(2), 5–18. https://doi.org/10.1016/S0973-0826(08)60396-8

Vaccari, M., Vitali, F., & Mazzù, A. (2012). Improved cookstove as an appropriate technology for the Logone Valley (Chad – Cameroon): Analysis of fuel and cost savings. Renewable Energy, 47, 45–54. https://doi.org/10.1016/J.RENENE.2012.04.008

1. Ph.D. en Ciencias Técnicas. Facultad de Ciencias. Escuela Superior Politécnica del Chimborazo. crecalde672000@yahoo.com

2. Ing. Mecánico. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. rafaelcordova24@yahoo.es

3. Ing. Electrónico. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. jonjhairo_gazzu@live.com

4. Ing. Mecánico. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. losmejores72@gmail.com

5. Ing. Electrònico. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. dflp20@yahoo.es

6. Egda. Ing. Quìmica. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. prynces87@hotmail.com

7. Biofísico. Grupo de Energías Alternativas y Ambiente. Escuela Superior Politécnica del Chimborazo. map_1090@hotmail.com