Vol. 38 (Nº 42) Año 2017. Pág. 28

Salima MIZANBEKOVA 1; Altynsary UMBETALIEV 2; Aigul AITZHANOVA 3; Renat AKYLBAEV 4

Recibido: 14/07/2017 • Aprobado: 30/07/2017

ABSTRACT: The purpose of this article is to develop priorities of mixed fodder production development in the Republic of Kazakhstan as a basis of livestock/poultry husbandry efficiency improvement in a cross-sectoral integration and competition that are common for emerging countries, as well as to develop guidelines for improving mixed fodder enterprise activity in the Republic of Kazakhstan in the context of transition to a market economy. We have analyzed the effectiveness of mixed fodder enterprises of the Republic of Kazakhstan and found the most effective available areas for feed enterprise activity improvement oriented on emerging countries. We have allocated the strategic priorities of mixed fodder production development in the Republic of Kazakhstan and developed guidelines for its success. Current situation with mixed fodder production development in emerging countries is characterized in the context of the Republic of Kazakhstan. We have considered features and problems of mixed fodder production development and revealed that sown areas are advisable to be optimized to provide enterprises with feed, as well as the process technology. We have analyzed the condition of fodder resources and considered areas for field culture development by domestic producers. We have substantiated the relevance and highlighted the prospects of mixed fodder production development in the context of cross-sectoral integration and competition. Developed guidelines for creating industrial clusters aimed at a multiplicative socio-economic effect will contribute to sustainable development of mixed fodder production. Therefore, public demands in food quality and safety solutions of economic problems will be satisfied. |

RESUMEN: El objetivo de este artículo es desarrollar las prioridades del desarrollo de la producción mixta de forrajes en la República de Kazajstán como base para la mejora de la eficiencia ganadera / avícola en una integración intersectorial y competitiva común a los países emergentes, así como para desarrollar directrices Para mejorar la actividad de las empresas mixtas de forraje en la República de Kazajstán en el contexto de la transición a una economía de mercado. Hemos analizado la eficacia de las empresas de forraje mixto de la República de Kazajstán y hemos encontrado las áreas disponibles más eficaces para la mejora de la actividad de las empresas de piensos orientadas a los países emergentes. Hemos asignado las prioridades estratégicas del desarrollo de la producción de forraje mixto en la República de Kazajstán y hemos elaborado directrices para su éxito. La situación actual del desarrollo de la producción mixta de forrajes en los países emergentes se caracteriza en el contexto de la República de Kazajstán. Hemos considerado características y problemas de desarrollo de producción de forraje mixto y reveló que las áreas sembradas son aconsejables para ser optimizado para proporcionar a las empresas con piensos, así como la tecnología de proceso. Hemos analizado la condición de los recursos forrajeros y hemos considerado áreas para el desarrollo del cultivo de campo por los productores nacionales. Hemos comprobado la pertinencia y destacado las perspectivas de desarrollo de la producción mixta de forrajes en el contexto de la integración intersectorial y la competencia. La elaboración de directrices para la creación de conglomerados industriales destinados a un efecto socioeconómico multiplicativo contribuirá al desarrollo sostenible de la producción de forrajes mixtos. Por lo tanto, las demandas públicas en la calidad de los alimentos y las soluciones de seguridad de los problemas económicos serán satisfechas. |

World practice shows that the use of complete feed allows receiving the maximum amount of animal products while reducing the amount of used feed for producing milk, meat, eggs and other livestock products (Baranski et al., 2014, pp. 794-811; Gain, & Roberts, 2001, pp. 229-235; IFIF, 2014). Production and feeding animals with large amounts of concentrated feed will allow increasing the productivity and reducing amount of used feed for producing meat, eggs and milk. Mixed fodder, balanced in terms of main analytical constituents, provides an increased producing ability of animals – by 10 - 12%, while enriching them with vitamins, antibiotics, minor elements and other means will increase it by 25 - 30% or more (Alshanov, 2006).

Since mixed fodder production is of prime importance for livestock/poultry husbandry efficiency in its performance and development, the study of current trends in agricultural production of emerging countries is quite relevant. In one of these countries – the Republic of Kazakhstan, there are prerequisites for mixed fodder production development: environmental conditions, human resources, orientation on providing environment for agricultural sector development (Rey et al., 2016, pp. 9679-9691). Identification of modern prerequisites and factors influencing mixed fodder production development is one of the major challenges in developing measures for this industry promotion and development in the Republic of Kazakhstan.

Currently, the level of mixed fodder production in the Republic of Kazakhstan does not meet the livestock husbandry requirements both in quantitative and qualitative terms. Their percentage of total concentrated feed consumption does not exceed 20%, while about 3.0 million tons of grain is used in the form of simple mixtures or ground.

In terms of mixed fodder production, People's Republic of China is at the first place – 189 million tons, the second place – USA (169 million tons), the third place – Federative Republic of Brazil (67 million tons) (Tireuov, 2011a). According to the FEFAC, European countries use corn as a base for mixes fodder (48%), as well as seed cake and meal (28%), and food processing products (12%); mixed fodder may also consist of beans (about 2%) and dairy processing products (1%) (Tireuov, 2011b).

The main research areas of modern science in studying the problems of efficient enterprise management in agricultural sector necessary in allocating priorities of mixed fodder production development in emerging countries:

Certain authors, (Finke, 2013, pp. 27-36; IFIF, 2014; Hao et al., 2014, p. 288) consider problem solution in mixed fodder production only as an action attributable to problem solutions of forming and developing poultry and grain sub-complexes, of rational feeding, grain fodder use, livestock/poultry husbandry efficiency improvement. This is also an unfounded and a narrow approach to solving specific problems of mixed fodder sector as a system of interacting economic agents. At the same time, it should be noted that feed mill industry is considered as a specific sphere of economic activity (Średnicka-Tober et al., 2016, pp. 994-1011; Cassidy, 2013, pp. 15-34).

The role and priorities of mixed fodder production development in sectoral structure of regional agro-industrial complex of emerging countries, in particular of the Republic of Kazakhstan, remain without due attention. In some extent, there was an attempt to take into consideration the specificity of emerging countries. In particular, V. Afanasyev has carried out a research on retrospective nature of mixed fodder production based on the engineering support in the Russian Federation starting with the 20-ies of the last century (Afanasyev, 2008a, pp. 4-9). In addition, the "provision of high-quality animal feedstuffs in most determines the level of development and the economics of agriculture growth, as the share of feed in the cost of livestock husbandry production is 65 - 75%. Therefore, feed mill industry remains an important link in agro-industrial complex development of the country" (Afanasiev, 2008b, pp. 9-13). At the same time, these studies are retrospective in nature, without regard to potential and prospects of mixed fodder production development in emerging countries.

Therefore, system analysis of mixed fodder production development in emerging countries is required as it is a basis for livestock/poultry husbandry efficiency improvement.

The purpose of this article is to develop priorities of mixed fodder production development in the Republic of Kazakhstan cross-sectoral integration and competition that are common for emerging countries, as well as to develop guidelines for improving mixed fodder enterprise activity in the Republic of Kazakhstan in the context of transition to a market economy.

Achieving this goal is related to the following objectives:

The results of this study are primarily aimed at ensuring the effective long-term feed enterprise management and development in emerging countries, as these issues had not been resolved in the scientific world until this research. This is the case of Central Asia (the Republic of Kazakhstan, etc.) and the former Soviet republics, which agricultural production differs from accepted standards in countries with market economy at all levels (in particular, mixed fodder).

This article is written due to a necessity in determining and substantiating the priorities for mixed fodder production development that are the most effective for the Republic of Kazakhstan and similar emerging countries with due account for the specifics of their economy, geography and agriculture.

Feed enterprises of the Republic of Kazakhstan are the object of this study, as they are common for emerging countries in terms of industrial and institutional framework.

The methodological basis of the study involves a system method of learning the laws of enterprise development, as well as a number of specific methods that give the opportunity to study in detail the areas of mixed fodder production development in emerging countries (for example, Kazakhstan). In particular, we have used the following methods: analysis and synthesis – to study the nature and cause-effect relationships between history, the current level of mixed fodder production development in the Republic of Kazakhstan in general and businesses in particular, and the prospects of its development. They were also used to study the development trends of phenomena and processes in mixed fodder production of the Republic of Kazakhstan.

We have also used a comparative analysis of various areas of technological and organizational development of mixed fodder production in the Republic of Kazakhstan as an emerging country and in developed countries. This allows developing guidelines for regional agro-industrial cluster implementation.

Feed enterprise activity analysis and assessment is based on the methods of primary data collection and processing, comparative method, methods of systematization and generalization.

Methodological instruments involve an empirical base of feed enterprises of the Republic of Kazakhstan, in particular: fodder production at the "East Kazakhstan Flour and Feed-milling Plant" JSC (the Republic of Kazakhstan, East Kazakhstan Region, Semey city). We have also considered a Karaganda regional agro-industrial cluster that provides the processing enterprises with forage crops (barley, oats) and a South-Kazakhstan Regional Investment Center (RIC) "Maximum" LLP.

In socio-economic modernization (main vector of Kazakhstan's development), livestock husbandry and feed production development are major challenges for the next decade, which potential is evidenced by the fact that the Republic of Kazakhstan has the fourth place in terms of feed production and the third one in terms of poultry feeds among the former Soviet republics. Its export capacity was 50% of meat products for the entire Soviet Union.

In 1990, it produced 4 million tons of mixed fodder and protein-vitamin supplements, including 1 million 300 tons of poultry feed. The share of complete feed in mixed fodder production of the Republic of Kazakhstan is 80%. For comparison, its share in Russia is 60%, while in Ukraine – about 50% of the total production (Afanasyev, & Myasnikova, 2005). Feed mill products was produced in Kazakhstan for 45 types of industrial and agriculural age-gender groups of live-stock animals, birds, fish and rabbits.

Complete feed mill production has to be increased up to 3.0 million tons per year by 2020 to meet the requirements of livestock/poultry husbandry and fishing sector. In this case, it is planned to build 28 feed plants with the capacity up to 100 tons per day at the grain procurement enterprises, as well as 72 modular plants with the capacity up to 20 tons per shift at the agro-industrial complexes and farms. In addition, it is necessary to reconstruct and modernize the 20 current feed enterprises and to introduce new advanced technologies (Tireuov, 2011a).

In emerging countries, especially in the post-Soviet countries, the technical base of production is subject to considerable obsolescence and physical deterioration. Thus, it has to be updated by means of innovative technologies related to raw materials and equipment, and by creating new agro-industrial clusters. High-tech feed mill production is a missing link in the chain of efficient mixed fodder production, providing strong economic performance in feed mill industry and in livestock husbandry.

Livestock animals graze on degraded grasslands and crop residues due to the lack of fertile pastures in many agricultural enterprises of the Republic of Kazakhstan. In winter, cattle are being fed with straw, partly with concentrated feed crops. The lack of digestible protein in animal diets (25-30%) entails the increase of feed amounts per unit by 1.3-1.5; producing ability reduces to 30-35%, and production costs increase.

In this case, the use of high-protein wheat (the most valuable food raw materials) does not make economic sense due to unresolved demand for it.

Despite the high proportion of grain components in mixed fodder production, the location of the livestock industry branches is a main determinant in capacity territorial distribution.

Thus, the Almaty District provides only 2.1% of total grain production in the Republic. However, the rate of stocking (7.2%) has determined the construction of 13.2% of feed mills. Semipalatinsk District provides 3.4% of grain, 7.3 % of stock and 9.9% of capacity; Karaganda District –3.4%; 4.6% and 9.1%, respectively (Tireuov, 2011b).

At the same time, regions with sufficient amount of raw materials in feed mills do not correspond to livestock husbandry needs. For example, Kostanay District provides 18.7% of the total grain production in the republic and 9.4% of stock. However, the share of its production capacity is only 5.8%; in the Urals – 6.1%, 5.8% and 20%, respectively; in Akmola District – 12%; 6.9% and 3.3%.

Wrong location of facilities and disproportion of their capacities in relation to grain raw materials result in significant interregional transportations of raw materials and mixed fodder.

In 2012, the volume of transported feed has reached 600 thousand tons, which is 20% of their production. Therefore, location improvement measures of feed mills are required in view of future-oriented trends in livestock husbandry development in the country. The same applies to different lines of mixed fodder production (Tireuov, 2011b).

Currently, the actual product range involves feed for pigs (46%) and poultry (38.7%), less for cattle (15%) and sheep (8%). Such a structure can be saved. In this case, demands of cattle husbandry and sheep husbandry should be met by producing mixed fodder on farms. However, there is only 0.4 % of plants for mixed fodder production. As a result, about 5.0 million tons of concentrated feed (50%) is fed to animals in the form of ground grain or without processing.

Grain fodder processing into complete mixed fodder is hardly doable due to poor non-grain part (fats, tankage, fish-meal, nonfat milk solids, milk replacers, vitamin supplements, dry yeast), which share now amounts to 20%.

Feed mills are raw material intensive – they use more than 50 kinds of raw materials and provide the same number of different mixed fodders. This involves complex manufacturing economic relations between suppliers and consumers.

However, these relations are insufficiently regulated. Short supply of protein supplements at the feed-milling establishment results in a negative trend of increasing share of grain components in using raw materials. Thus, the share of grain components has risen from 52.4% in 2007 to 60% in 2013, namely, by 7.6 points (Tireuov, 2011a).

Currently, the amount of protein-vitamin supplements and carbamide concentrates in departments producing mixed fodder on farms, satisfies only 25-30% of demand. The volume of protein-vitamin supplements produced over the past 15 years did not increase, but declined causing poor provision of feed-milling establishments with protein components.

As a result, the available capacity of departments covers only 400-500 thousand tons of mixed fodder per year (10-15% of republican production). Mixed fodder production has to be increased based on raw materials not only with protein-vitamin supplements of industrial production, but also with local protein resources.

In assessing the economic efficiency of mixed fodder production of the Republic of Kazakhstan, we should note that the level of profitability calculated as the profit-to-total cost ratio is low and amounts to 2.3%. This is due to the low technical level of enterprises that do not meet modern requirements to production. Thus, the share of modern machinery and equipment is only 45%. The share of enterprises and departments with modern equipment is only 33%, 15% are subject to reconstruction, 44% – to technical re-equipment. Actually, about 8% of the equipment has to be written off. In general, depreciation of fixed assets is 40% due to the extensive basis of the process, namely, due to the prime increase of fixed assets under a small percentage of their disposal.

"East Kazakhstan Flour and Feed-milling Plant" JSC (the Republic of Kazakhstan, East Kazakhstan Region, Semey city) is an example of innovative mixed fodder production development in the country, which operates more than 70 years in the market of the Republic of Kazakhstan and CIS countries. "East Kazakhstan Flour and Feed-milling Plant" JSC is one of Kazakhstan's largest manufacturer of complete balanced granulated and bulk feed.

"East Kazakhstan Flour and Feed-milling Plant" is a complex producing 15 000 tons of bulk feed and 8 000 tons of granulated feed per month. Modern equipment allows producing mixed fodders and middlings for all kinds of live-stock animals, birds and fish in any range and also customizing granulated and bulk feed according to agreed customer recipes. Technical re-equipment of the plant was held according to the project of «AtonInvest» LLC. This re-design of production facilities by means of modern technology, in the form of additional production capacities and the latest developments will eliminate the technical backwardness, to set up the production of high-quality fodder.

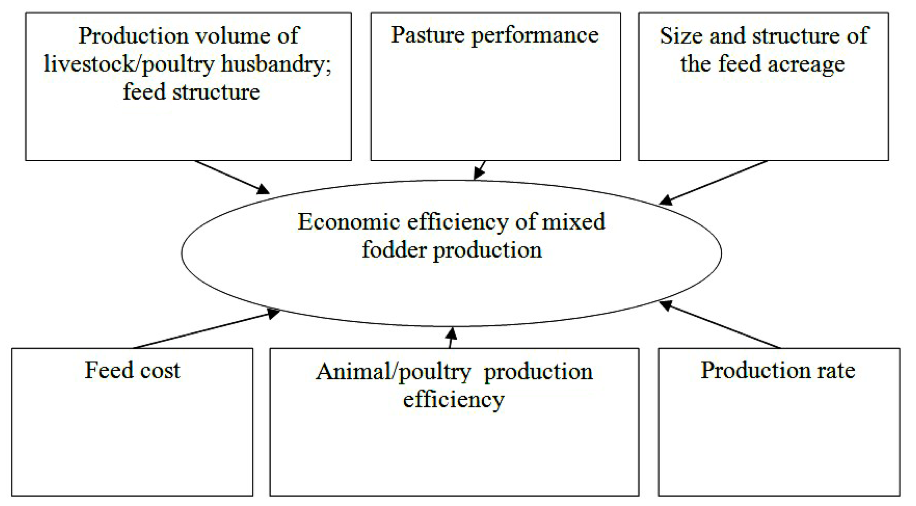

In modern economic environment, scientific organization of fodder resources – namely, its optimization – must comply with livestock husbandry, provide a balance between the level of mixed fodder production with proper structural composition and the actual demand for them, must be resistant to adverse environmental and other external/internal factors (Figure 1).

Figure 1. Economic efficiency factors of mixed fodder production

Livestock industry restoration and production structure optimization in integrated units is only possible with the necessary fodder resources. Production structure improvement is possible by creating fodder crop succession and high-protein crops with legume grasses near livestock farms. Fodder crop succession should be introduced in farms with insufficient natural forage lands. Winter and summer cereals, legumes or cabbage cultures and mixtures thereof shall be included as field crops in integrated farms with advanced livestock husbandry, for example – "East Kazakhstan Flour and Feed-milling Plant" JSC.

The concept of mixed fodder production development in integrated livestock farms ("East Kazakhstan Flour and Feed-milling Plant" JSC) should include the sown area improvement with due account for specialization, restoration of crop succession, its saturation with legumes and high-protein crops, fertilization program improvement and new technologies.

The study of the current situation in mixed fodder production of the Republic of Kazakhstan and a particular enterprise operation environment ("East Kazakhstan Flour and Feed-milling Plant" JSC) will provide an opportunity to highlight the priorities of its further development in accordance with modern trends in the global animal feed market.

In analyzing the world experience in mixed fodder production in developing economies, we have found a significant increase in their output in People's Republic of China, Federative Republic of Brazil, the United Mexican States and the Southwest Asia. These countries provide the growing demand for animal feed in the world economy – 612 million metric tons (Clayton Gill 2004) per year –. annual growth is about 1.5%.

In analyzing the problems and prospects of mixed fodder production development in the Republic of Kazakhstan as an emerging country, the performance of this industry should be compared with the experience of developed countries. Thus, in developed countries, scientists, specialists and investors study problems of mixed fodder production, production efficiency improvement and its resource base formation due their importance for national food market development (Izbassarov, & Kim, 2006). In particular, scientists substantiate the consumption rates for animal feed and develop technologies for their production; specialists introduce innovative technologies for mixed fodder production; investors fund research activities, mixed fodder production development and re-equipment.

At the same time, there are strong trends towards upstream integration and consolidation of mixed fodder production on an international scale in both developed and developing countries. Thus, less than 3.500 of feed-milling establishments produce over 80% of the world's animal feed.

The study of domestic and foreign experience shows that clusters are the main element in economy development. Clusterization has affected the production in such countries as the Kingdom of Denmark, Republic of Finland, Kingdom of Sweden and Kingdom of Norway.

According to experts, clusterization has covered about 50% of the leading countries in the world, including the USA, Italian Republic, Great Britain, French Republic, Federal Republic of Germany etc. (Enright, 2000). In modern world practice, agro-industrial cluster formation is one of the main ways to increase the efficiency of industrial enterprises due to a number of advantages over traditional methods of interaction: decreased costs for goods circulation, elimination of duplication and the overall synergy effect for each participant by means of a broader and more comprehensive integration.

Industrial cluster can be represented in the form of two main elements: the core – the main enterprises producing, processing and selling the products; the satellite – auxiliary plants that supply additional goods, jobs and services for the core business. At the same time, it must be formed based on existing organizations and enterprises in order to reduce organizational costs (OECD, 2007).

Karaganda Disrict of the Republic of Kazakhstan has started to create regional agro-industrial cluster on forage crops (barley, oats) provision by processing enterprises, involving farms with arable land and enterprises, providing services of scientific support for production, and animal feed consumers – poultry plants and pig farms.

This cluster enterprise-consumer made it possible to get local fodder grain at a reasonable price, which was purchased from the northern regions. This affected the product cost. Demand of these enterprises in barley is 4 900 thousand tons per year.

Cluster formation is also possible on the basis of a grain holding company “Batt Corporation” which includes 26 enterprises located in North Kazakhstan, Akmola and Kostanay Districts. Grain holding involves large grain processors – «Mamlyutsky Flour Mill» LLP and «Kzyltusky flour mill» LLP.

There have been already launched two innovative enterprises: "Biochim" in Taiynsha (North Kazakhstan Region) and the company Silicium Kazakhstan near Karaganda District with high-tech facilities, focused on deep high-level processing. In "Biochim", there are necessary facilities built for waste-free grain processing. "Biochim" releases supplements for gasoline that can repeatedly reduce the ecological stress and fibrin amount. Silicium Kazakhstan can produce silicon metal, demanded in many industries – from professional equipment to the aluminum industry. Both plants were designed with an eye toward international integration.

A high-tech facility was launched due to innovative project implementation – feed mill of German concern (Akmola District), which produces effective products for livestock holdings. Agricultural producers around the world know the AGRAVIS brand very well.

Investments in new production capacity of 15 tons per hour has amounted to about 8 million euro. The enterprise is applying new technologies in animal feeding, developed by AGRAVIS specialists after many years of experience. The plant is equipped with the line from the leading Swiss manufacturer Bühler, which has been installed by Bosche Systembau GMBH. Integrated European Quality Standards for animal feed production DIN EN ISO 9001: 2000, GMP +, HACCP and QS, composition of feeding programs and formula optimization for each holding and the laboratory for product testing, applying LIMS technology will become an integral part of up-to-date high-tech production cluster AGRAVIS in the Republic of Kazakhstan. The plant will produce not only structured bulk and granulated feed, but also – crumbled feed. In addition, the products will be delivered directly to the customers. Individual retail network was created for private subsidiary plots and farms that usually purchase small amounts of feed to realize concentrates and feed primarily for cattle and poultry. The products will be sold in the northern regions of the Republic of Kazakhstan and in a number of Russian regions – Siberia, the Urals and the Far East.

The capacity of the new production is 110.000 tons per year. Technological chain of the cluster will include the purchase of raw materials and components, production and sale of final products. New enterprise has practical access ways for motor vehicles and a railway line with possibility of raw materials receipt and shipment with capacity of 420 tons per day. System of feed production optimization meets all the necessary requirements, which guarantees the production of high quality animal feed. The production line at the plant is automated. This eliminates any human factor. Highly qualified specialists of AGRAVIS make feed formulas individually for each holding, taking into account peculiarities of feeding at a certain stage of development, as well as the specific client’s purpose: additional weight of meat, increased egg collection, milk yield, etc.

Implemented QM feed production quality system meets the highest German standards, which are among the most demanding in the world.

Modern FORMAT Single-MIX program optimizes all production processes and coordinates the operation of each AGRAVIS plant at a distance in real time. Thus, each feed formula is created in Germany and is added in a single database – the employees at the plant of the Republic of Kazakhstan have only to choose the right product in the system and send it to production. AGRAVIS, unlike most manufacturers, uses a grain cleaning technology to clean the grain from mycotoxins on animal feed production stage, eliminating the need for their adsorbing material in the future.

Project support in the field of processing for intensive livestock husbandry development is one of the priorities of the South-Kazakhstan Regional Investment Center (RIC) "Maximum" LLP. Fodder resources in both large and small-scale farms of the region limit livestock husbandry development. Demand for mixed fodder for animal production is 611.8 thousand tons per year.

In 2012, there were imported 74.4 tons of feed, including from Germany – 50 tons, the Kingdom of the Netherlands – 20.4 tons. Moreover, demand for animal feed is satisfied by transported feed from other regions of the country.

In 2013, department formation for mixed fodder production became to be one of the priorities of the "Maximum" LLP. RIC has allocated money to purchase equipment for feed granulation and working capital financing for three years. The main source of raw materials for feed production is wheat, corn, barley, sunflower, cotton and soybean meal, which will be purchased from agricultural producers.

It is planned to produce two types of animal feed: complete feed for chickens and concentrates for cattle. Complete feed satisfies the demand of animals or birds for nutrients, minerals and biologically active substances as the sole ration (chickens, ducks, geese, pigs, rabbits). Concentrates are used in combination with succulent and roughage feeds. Such feeding is used in relation to cattle of all ages and various productivity.

The Regional Investment Center "Maximum" has developed projects for animal feed production in each district of the region and determined the most appropriate technologies f and the types of equipment.

In describing the organizational aspects of feed production efficiency improvement in emerging countries (for example, the Republic of Kazakhstan), it should be noted that a key trend of feed mill industry development in the Republic of Kazakhstan is the production consolidation within the vertically integrated livestock holdings. The share of large integrated holdings in the overall feed production is more than 50%. However, small and medium-sized feed mills that do not have guaranteed marketing channels and reliable investment sources are characterized by a low level of capacity utilization.

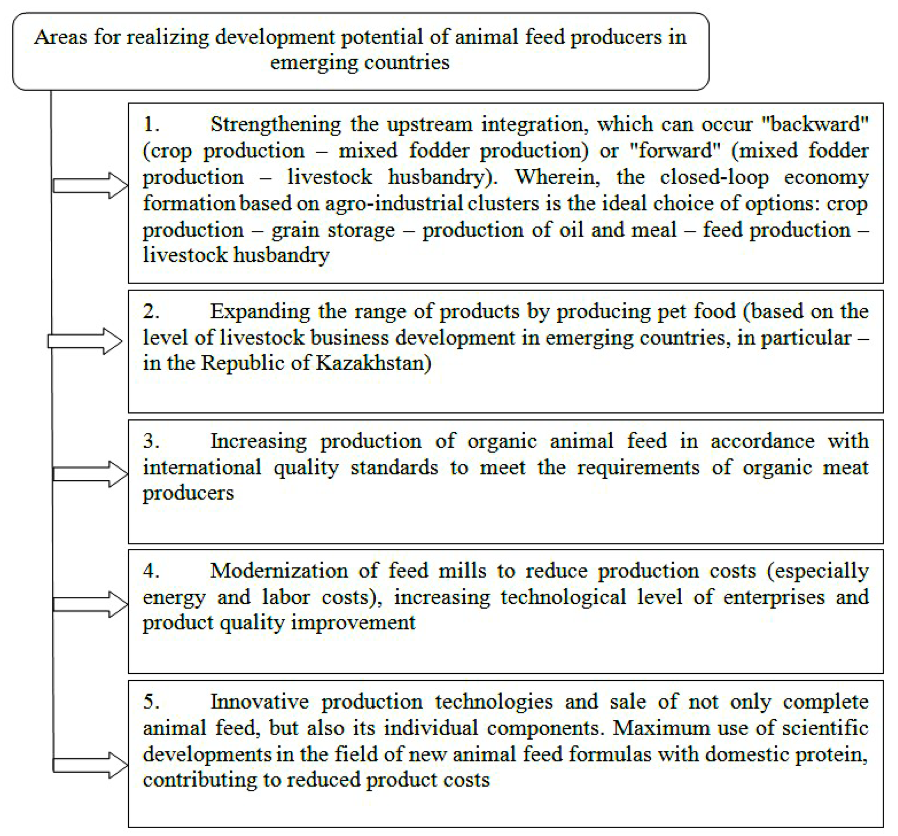

In our opinion, the following organizational areas are relevant for realizing development potential of animal feed producers in emerging countries (Figure 2)

Figure 2. Areas for realizing development potential of animal feed producers in emerging countries

In our opinion, organic production is the most attractive area for realizing the investment potential of those feed mills that have their own fodder resources, but are not related with powerful holdings, as the market of organic animal feed is only beginning to develop in emerging countries. This is due to the shortage of required amount of organic raw materials, lack of demand from consumers at existing prices and the lack of the necessary legal framework.

At the same time, organic production development is an extremely important issue. Since there is a growing demand and the basic environment is available, the intensive growth in organic feed production and meat production is only a matter of time. Intensive organic animal feed production development has certain limitations: a shortage of organic grain; low emphasis on improving the grain quality; lack of state financial support; low level of awareness about the appropriateness of organic product consumption and their positive impact.

The primary role in the complex of measures aimed at creating a reliable fodder resource base in emerging countries and improving its economic efficiency belongs to intensive factors of production organization. Organization of intensive mixed fodder production may significantly increase the feed production by:

Production of the sufficient amount of quality feed grain, animal feed and protein-vitamin raw material for the Kazakhstan’s enterprises requires:

its consumer properties;

subsequent milling;

Each of these methods requires special equipment and machinery. Thus, re-equipped production base is required in emerging countries.

Strategy basics for effective feed enterprise operation in emerging countries should be as follows:

Feed industry is expected to be developed in two directions.

The first is to strengthen the enterprise capacity while the production process is under intensification in order to fulfill the following challenges:

The second is to produce feed and feed mixes mainly for cattle and pigs in agricultural feed departments and at the plants by means of own raw materials, protein-vitamin supplements, mineral additives and industrial premixes.

This article is relevant in global sectoral research as it provides instruments for feed enterprise development, theoretical principles, developments and science-based conclusions that may be used as the organizational-economic mechanism of formation and as a guideline for regional cluster management.

Modern high-tech animal feed production is the missing link in efficient mixed fodder production, providing strong economic performance in feed industry and in livestock husbandry.

Currently, technical base of the feed industry in emerging countries is subject to significant obsolescence and physical deterioration and has to be updated by innovative technologies related to raw materials and equipment and by forming agro-industrial clusters. The capacity of feed industry allows increasing the animal feed production, but plants require modernization. Thus, feed industry development must be gradual by enhancing innovation capacity and improving material support efficiency.

We consider the agricultural sector growth in the emerging countries (for example, the Republic of Kazakhstan) as an ever-transforming activity in the market environment due to cross-sectoral integration. This allows sell not raw materials, but final animal production. It depends on the possibility of increasing the productivity (Furgal-Dieriuk et al., 2015, pp. 19-30) that determines the growth rate and the level of animal production. We determine two basic aspects of mixed fodder production in emerging countries (determined in the case of the Republic of Kazakhstan): technological and organizational. The first one involves specific recommendations on introducing innovative technologies of cultivation and raw material processing, realizing high biological potential of forage crops, on optimizing the sown areas in composition and in structure. The second one involves the cluster approach under cross-sectoral integration in emerging countries, as well as on the global animal feed market.

In this context, the primary role in the complex of measures aimed at creating a reliable fodder resource base in emerging countries and improving its economic efficiency belongs to intensive factors of production organization (Gu et al., 2014, pp. 1-13). Areas for feed industry development in the Republic of Kazakhstan are required to be determined in the context of feed industry dependence on agribusiness development in general. Thus, advanced technologies for growing fodder crops and increasing their yield level (Mohite et al., 2013, pp. 1373-1377) will significantly increase the feed production performance. More efficient fodder conservation and storage are important for livestock husbandry in general, and for animal feed industry, which uses feed as a raw material.

Feed composition improvement, namely – increased percentage of high-protein fodder crops is also important for emerging countries, as well as the use of advanced technologies for fodder processing and mixed fodder production according to international quality standards (Mahesh, & Madhu, 2013, pp. 4221-4231).

In particular, we provide specific guidelines for mixed fodder production development on base of "East Kazakhstan Flour and Feed-milling Plant" JSC (the Republic of Kazakhstan, East Kazakhstan Region, Semey city) and on base of regional agro-industrial cluster on forage crops (barley, oats) provision by processing enterprises in Karaganda District and South-Kazakhstan Regional Investment Center (RIC) "Maximum" LLP.

This article is relevant due to specific recommendations for feed industry development that might be interesting for researchers in the field of agricultural science, for heads of enterprises and for certain authority.

This article is devoted to determination of priorities for feed industry in emerging countries (for example, the Republic of Kazakhstan) in a cross-sectoral integration and competition that are common for emerging countries. This issue was resolved by analyzing the feed enterprise efficiency in the Republic of Kazakhstan. Thus, we have determined the main problems of the industry.

The main economic efficiency factors of feed production are the size and structure of the feed acreage, pasture performance, production volume, production rate, the feed cost and animal production efficiency.

We have allocated the most effective available areas for feed enterprise activity improvement oriented on emerging countries and grouped them according to two aspects of animal feed production development at the enterprise level: technological and organizational.

In terms of technological aspect, we have highlighted specific actions recommended for implementation in Kazakhstan’s businesses. In terms of organizational aspect, we have proved the importance of cluster development in agro-industrial complex in the emerging countries to improve their efficiency in modern conditions. Therefore, this article provides guidelines for mixed fodder production development and for feed enterprises improvement in the context of transition to a market economy of the Republic of Kazakhstan.

Our study indicated that fundamental reforms are necessary, including the implementation of innovative technologies, new raw materials and equipment. The relationships between industrial enterprises, business partners and government have to be reorganized. Developed guidelines for industrial cluster formation, focused on multiplicative socio-economic effects, will contribute to a sustainable mixed fodder production development that satisfies public demands for food quality and solutions of Kazakhstan’s economic problems.

Afanasiev, M., & Myasnikova, L. (2005). World competition and clusterization. Economy Questions, 4, 79 – 86.

Afanasyev, V. (2008a). The feed mill industry of Russia: the past, present and future. Compound Feeds, 7, 4 - 9.

Afanasyev, V. (2008b). Mixed fodder production: situation and challenges. Compound Feeds, 1, 9 – 13.

Alshanov, R. A. (2006). Kazakhstan in the world grain market. Raritet: Almaty.

Baranski, M., Srednicka-Tober, D., Volakakis, N., Seal, Ch., Sanderson, R., & Stewart, G.B., et al. (2014). Higher antioxidant and lower cadmium concentrations and lower incidence of pesticide residues in organically grown crops: a systematic literature review and meta-analysis. British Journal of Nutrition, 112, 794-811.

Cassidy, E. S., West, P. C., Gerber, J. S., & Foley, J. A. (2013). Redefining agricultural yields: from tonnes to people nourished per hectare. Environmental Research Letters, 8(3), 15-34.

Enright, M. J. (2000). Survey on the Characterization of Regional Clusters: Initial Results. Available at: http://www.acdivocacoopex.org.

Finke, M. D. (2013). Complete nutrient content of four species of feeder insects. Zoo Biology, 32, 27-36.

Furgal-Dieriuk, I., Strzetelski, J., Twardowske, M., Kwiatek, K., & Mazur, M. (2015). The effect of genetically modified feeds on productivity, milk composition, serum metabolite profiles and transfer of tDNA into milk of cows. Journal of Animal and Feed Sciences, 24, 19-30.

Gain, G., Roberts, G. (2001). Evaluation of egg mass as a selection criterion in chickens. Indian Vetererinary Journal, 57(3), 229-235.

Gill, C. 2004. China, Brazil, Mexico, push global nage to new peak. Feed International, 25(1), 6-9.

Gu, J., Bakke, A.M., Valen, E.C., Lein, I., & Krogdahl, A. 2014. Bt-maize (MON 810) and non-GM soybean meal in diets for Atlantic Salmon Juveniles - impact on survival, growth performance, development, digestive function, and transcriptional expression of intestinal immune and stress responses. PLOS ONE, 9, 1-13.

Hao, H., Cheng, G., Iqbal, Z., Ai, X., Hussain, H.I., & Huang, L., et al. (2014). Benefits and Risks of Antimicrobial Use in Food-Producing Animals. Frontiers in Microbiology, 5, 288.

IFIF. (2014). What is the global feed industry? International Feed Industry Federation Factsheet. Wiehl, Germany: International Feed Industry Federation.

Izbassarov, A., & Kim, A. (2005). Scientific-technical progress in GDP dynamics of Kazakhstan. Moscow: Vita-Press.

Mahesh, M. S., & Madhu, M. (2013). Biological treatment of crop residues for ruminant feeding. African Journal of Biotechnology, 12(27), 4221-4231.

Mohite, B. V., Chaudhari, G. A., Ingale, H. S., & Mahajan, V. N. (2013). Effect of fermentation and processing on in vitro mineral estimation of selected fermented foods. International Food Research Journal, 3, 1373-1377.

OECD. (2007). Reviews of Regional Innovation: Competitive Regional Clusters: National Policy Approaches. OECD Publishing: Paris.

Rеy, I. U., Shakulikova, G. T., Kozhakhmetova, G. A., Lashkareva, O. V., Bondarenko, E. G., & Bermukhambetova, B. B., et al. (2016). Labor Factor Efficiency in the Agricultural Industry. International Journal of Environmental and Science Education, 11(17), 9679-9691.

Średnicka-Tober, D., Baranski, M., Seal, Ch., & Sanderson, R. 2016. Composition differences between organic and conventional meat; a systematic literature review and meta-analysis. British Journal of Nutrition, 115(6), 994-1011.

Tireuov, K. M. (2011a). Agriculture of the Republic of Kazakhstan: innovative development. Almaty.

Tireuov, K. M. (2011b). Agribusiness economics. Almaty.

1. Kazakh National Agrarian University, Almaty, Kazakhstan. E-mail: Salima-49@mail.ru

2. Shymkent University, Shymkent, Kazakhstan. E-mail: rsaliev_beibut@mail.ru

3. University of Foreign Languages and Business Career, Almaty, Kazakhstan. E-mail: a.aitzhanova@mail.ru

4. Eurasian Technological University, Almaty, Kazakhstan. E-mail: rina-888@mail.ru