HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN Espacios. Vol. 37 (Nº 22) Año 2016. Pág. 17

Carlo Alessandro CASTELLANELLI 1

Recibido: 30/03/16 • Aprobado: 12/04/2016

ABSTRACT: Recycled wood-based board is treated to produce a base material of heating system and has two important functions for sustainable development, as an industrial resource and as a means of longer storage of fixed carbon from carbon dioxide by photosynthesis. In this study, it was evaluate the environmental effects of wood-based heating system, to replace an old heating system in industrial processes of a German musical instruments manufacturer. The replacement of natural gas combustion for heating by wood waste and wood pellets systems has been investigated by a streamlined LCA. When comparing new and old system technology, the results show that the new technology contributes to a significantly improved performance (25–81%) for all types of environmental impact studied. There is a significant difference in the life cycle performance of a wood heating systems using modern technology versus older technologies. In addition, in this case the wood leftovers are locally produced. |

RESUMEN: Los reciclados con base de madera son tratados para producir un material base para los sistemas de calefacción y tienen dos funciones importantes para el desarrollo sostenible: como un recurso industrial y como un medio de almacenamiento más largo de carbón fijo de bióxido de carbono. En este estudio, Se evaluaron los efectos ambientales del sistema de calefacción con base de madera, para reemplazar un viejo sistema de calefacción de un fabricante de instrumentos musicales alemán. La sustitución de la combustión de gas natural para calefacción por pellets de madera y residuos de madera han sido investigados por un ACV aerodinámico. Al comparar la tecnología de sistemas nuevos y viejos, los resultados muestran que la nueva tecnología contribuye a un rendimiento significativamente mejorado (25 – 81%) para todos los tipos de impacto ambiental estudiado. Hay una diferencia significativa en el rendimiento del ciclo de vida de madera usando la tecnología moderna versus tecnologías antiguas de sistemas de calefacción. Además, en este caso los restos de madera son de producción local. Palabras clave: Reciclar; Residuos de madera; Ahorro de energía. |

Wood products are often found to have lower environmental impacts when compared to functionally equivalent products from fossil or mineral resources (Sathre and O'Connor, 2010, Werner et al., 2005 and Werner and Richter, 2007). Raw material acquisition and production requires less fossil based energy, which leads to overall reduced environmental impacts and therefore creates benefits if substituting conventional materials. If utilized as fuel, wood can substitute for the diminishing fossil energy carriers.

Also, electricity market prices have increased rapidly in recent years, which makes important to produce and sell additional electricity because this is an important factor in determining a heating plant's profitability (Babic, 2010). There are numerous studies that emphasize the potentials of renewable energy, or more specifically bioenergy, in district or residential heating and in combined heat and power systems (CHP) (Ghafghazi et al., in press and Campbell et al., 2011). However, the use of biomass for district heating has been quite controversial due to concerns with possible increase in health impact (Ries et al., 2009).

Biomass as a part of the bioenergy is the name given to any organic matter which is derived from plants. That is plant and animal materials such as wood from forests, crops, seaweed, material left over from agricultural and forestry processes, and organic industrial, human and animal wastes. Biomass is a general term which includes phytomass or plant biomass and zoomass or animal biomass. The sun's energy when intercepted by plants and converted by the process of photosynthesis into chemical energy, is 'fixed' or stored in the form of terrestrial and aquatic vegetation. The vegetation when grazed (used as food) by animals gets converted into zoomass (animal biomass) and excreta. The excreta from terrestrial animals, especially dairy animals, can be used as a source of energy, while the excreta from aquatic animals gets dispersed as it is not possible to collect it and process it for energy production Oregon. Biomass energy.

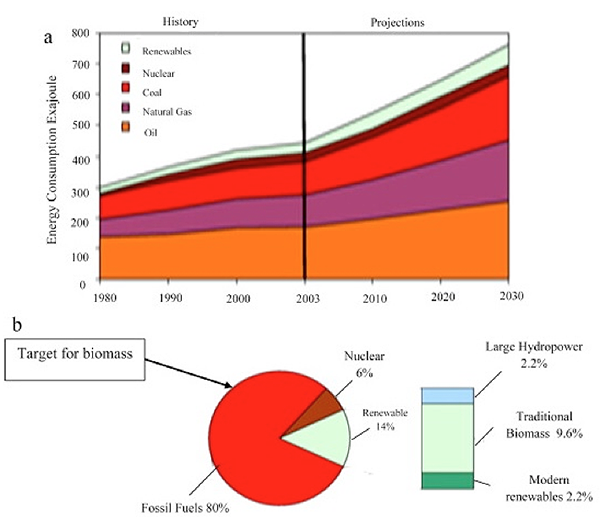

Fig. 1 – Biomass utilization projections.

The origin of fossil fuels comes from deep in the earth, contained in animal and vegetable substances which have evolved over millions of years by chemical and physical processes. The main component of the chemical element is carbon, which is oxidized by the action of oxygen to carbón dioxide (CO 2). The intensive use of fossil fuels in both senses can be a problem for the future of the earth. On the one hand threatening the natural resources, as in the case of petroleum, which in the foreseeable future will be scarce or dry up altogether. Secondly, the daily carbon dioxide produced by fossil fuels as a greenhouse gas burden our atmosphere in an objectionable manner. Greenhouse gases absorb the sunlight reflected from the Earth and as a result show an increase in extraordinary global warming.

Science doesn't yet agree about the exact impact of the greenhouse effect itself. However, it is not to be dismissed, that even today a massive impact on the global climate is being felt. The problem of global warming in recent decades resulted in a measurable increase in the average temperature in the atmosphere and in the oceans.

Right now, having a minimal increase in temperature can have a devastating effect, as can be seen by increasing melting of the icecaps and the consequent rise in sea level. The resulting climate changes have recently led to an increase in devastating environmental disasters such as Tornadoes, floods and droughts.

Forests have two important roles from the viewpoint of sustainable development; the first is fixing carbon from carbon dioxide in the air through photosynthesis, combating global warming; the second is providing a sustained supply of wood as a renewable industrial and energy resource, different from finite resources such as metals, coal and oil.

The recycling of wood-based materials effectively addresses problems of waste treatment and lack of resources. In spite of such advantages of wood for sustainable development, problems with wood resources, such as the increase of wood building waste, have been observed. (Khan et al, 2009).

Due to the continuous expansion of administrative buildings, production and storage facilities and office buildings at the target company in recent years, the demand for heating energy at the company increased rapidly. This would probably devour huge costs, in addition to the measures taken for thermal insulation is a further step for the heating systems on the cutting edge of technology. It is a benefit to the environment and for economic reasons, and for effective alternatives to traditional fuels such as gas and oil.

The company has invested a total sum of 8.94 million euros to present date in measures to increase the heating efficiency. These investments are expected to provide independent heating of the entire corporate complex with the renewable energy sources of wood, so that conventional fuels are no longer needed.

The replacement of natural gas combustion for heating by wood waste and wood pellets from the manufacturing of wood guitars and basses has been investigated by a streamlined LCA, concerning the environmental impacts.

Life Cycle Assessment (LCA) has been defined by Society of Environmental Toxicology and Chemistry (SETAC) "as an objective process to evaluate the environmental burdens associated with a product, process or activity, by identifying and quantifying energy and materials used and waste released to the environment, and to evaluate and implement opportunities to effect environmental improvements" (Barton et al., 1996). LCA is a methodology for examining environmental impacts associated with a product, process or service ''from cradle to grave''– from production of the raw materials to ultimate disposal of wastes. LCA was developed in order to take into account issues that are not addressed by other environmental management tools such as statutory environmental impact assessment. It has proved itself particularly useful as a technique for comparing two or more alternative options in terms of their combined potential environmental impacts and ecological sustainability.

According to ISO 14 040, allocation is defined as partitioning the input or output flows of a unit process to the product system under study. Allocation means that the environmental aspects are partitioned among the different products and/or among subsequent product systems. Three generic processes for allocation are distinguished:

- multi-Output processes providing e.g. sawn timber, sidecuts and sawdust from the sawmill, where the material flows of the process and its up-stream processes have to be allocated to the various outputs,

- multi-Input processes, e.g. the combustion of different fractions of waste wood, where the emissions and the generated energy have to be allocated to the different products or product systems,

- Recycling and reuse, where, besides the recycling process itself, primary production and final disposal may have to be allocated to several subsequent product systems.

LCA is an appropriate methodology for biofuels analysis, and has been used in other studies, in particular Bioenergy Options (Hall and Gifford 2008). An internationally accepted framework for LCA methodology is defined in ISO 14040 and 14044 (International standardisation organisation 2006). Four different phases can be distinguished: 1. Goal and Scope Definition 2. Inventory Analysis 3. Impact Assessment 4. Interpretation This Life Cycle Assessment was performed following the ISO14040 guidelines.

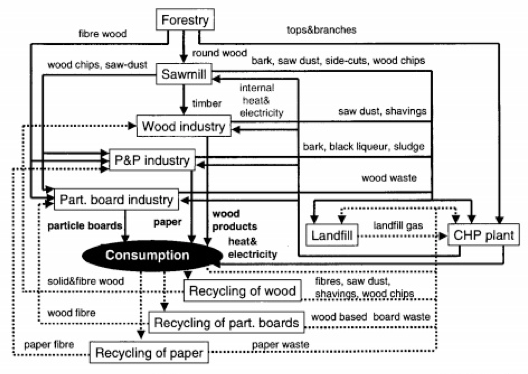

Fig. 2. Processes in the LCA of wood-based products

In LCA of forest products, energy generation from wood (bioenergy) might substitute fossil energy. It is a continuous debate among LCA-practitioners, which energy sources are substituted when wood is used for bioenergy. In addition to the goal and scope definition of the specific LCA study, the treatment of substitution is dependent on the following criteria:

- kind of energy output (e.g. fuel, electricity, heat, electricity and heat)

- Quality of energy output (e.g. temperature, voltage, ratio between electricity and heat)

- energy supply/demand characteristic (e.g. base load, peak load, summer, winter, distribution, additional energy supply)

- state of technology (e.g. average substitutes average, new/ old, new/new, new/average)

- kind of fossil fuel substituted (e.g. coal, lignite, natural gas, oil)

- costs (e.g. low substitutes high, high/high, medium/high, high/low)

The target company is a Germany-based bass and guitars manufacturer company, originally a premium brand offering a small range of models built from high quality and exotic tonewoods. The company also produces Valve and FET amplifiers, speaker cabinets, bass guitar strings, and is the division of the Framus trademark. Their headquarters and custom shops are located in Markneukirchen, Shanghai, and Nashville.

In 1994, the company began to invest in ecological and energy saving measures with na ingenious concept to gradually modernized some parts of the company. An idea of how much these measures save energy and protect the environment, as well as what we are prepared to pay and can cost in the near future, will be listed below in a table with concrete numbers of all investments in this field. Nevertheless, the investments will pay off in the medium to long term, and indeed in two ways: from an economic perspective and for the benefit of the environment. This results in a win-win situation in which everyone benefits.

The Company is investing in alternative energy sources. The concept here is the wood that is obtained as a waste product in the company´s daily work, made sense to convert it into heat energy. In this way one has a lasting answer to a cost explosion, caused by rising energy prices. In addition, the company makes a valuable contribution to environmental protection, as this process produces a much lower emissions of environmentally harmful greenhouse gases. Of course, the realization of new heating systems, in addition to the environmental concept, has always played a big role in the economic profitability. For it is only when these two aspects go hand in hand, both sides benefit - the environment and the company. The company has gradually converted its heating system from the use of fossil fuels to an effective utilization of renewable energy, which you will learn in the following sections.

In the mid-nineties gas heating was still one of the most economical forms of heating. Therefore in 1994 it was decided at the company to install a new gas heating system with 350 kW capacity, which would supply the entire complex with heat. The investment for this measure amounted to 53,550 euros. In the following 15 years the successive introduction of alternative and environmentally friendly heating systems reduced the operation of the gas heater until it was finally was taken out of service in 2005. Currently, it serves purely as emergency heating, should the outdoor temperature fall below 15 degrees or less.

In 2005, the company was already thinking about how we can reduce the immense gas consumption by recycling the resulting waste wood. The use of Wood waste is more environmentally friendly than the firing with gas, since during the combustion of the wood just as much carbon dioxide (CO 2) is released as the tree absorbed during its growth phase. The carbon economy is here, well below the value obtained in the use of traditional fuels. Thus, a recycling of wood waste is a sustainable benefit to the environment, and contributes to the reduction of the greenhouse effect and the threat of climate change.

The wood waste generated during production is fine wood chips that are incurred during the sawing, grinding, etc. For larger wood chips, from the remnants of the raw material waste, a span stove with a heat output of 400 kW was installed. During machine processing the fine chip material is blown into a silo, which is located above the clamping furnace. The silo is automatically supplied to the underlying tension oven where the chip material is ultimately transformed into an environmentally friendly heating energy. The investment cost for this plant totaled 130,000 euros.

The environmentally sound recycling of waste wood is good, but preventive avoidance of wood waste is even better. Therefore, a strategy on the prevention of material was devised. A new Copy-band saw was purchased to cut desired shapes out of the wood with the minimum waste.

The daily resulting wood waste was burned initially in a 31 kW log boiler, where previously the coarse wood waste is shredded in a chopper. From 2005, a 150-kW log boiler replaced the old system and made the vibrator superfluous. In 2008, a further upgrade was performed on the log boiler with 250 kW and a capacity of 1.35 cubic meters, allowing up to 1.2 meters long pieces of wood to be burned. This system has really nothing to do with the traditional idea of a smoky wood stove, on the contrary, the modern firewood furnace keeps strictly to the lowest emission values and is constantly monitored and maintained by qualified professionals. This new, environmentally friendly technology was installed at a cost of 77,350 euros.

Through the use of a production waste chip furnace and log boiler an autonomous heat supply was ensured for a total factory area of 13,000 m2. Is forecasted to heat the entire corporate complex with wood waste and the company to become completely independent of gas and oil. Although it is entirely dependent on the raw material Wood as fuel, this presents no problem, as this raw material is obtained as waste every day in production.

Chip and log boiler furnace ensure an independent supply through the use of production waste for the following areas:

- Production area: 3,000 m2

- Storage area: 10,000 m2

- Drying chamber Lauber: 18 kW

- Drying chamber Muhlbock: 100 kW

- Muhlbock vacuum drying chamber: 62 kW

- Spray room and oven: 150 kW

The best heating systems can only work efficiently if it is coordinated with the help of a central control and regulation system in an optimal way. Modern computer technology is now making its debut in the field of regulation and control of heating systems.

As part of the rebinding of the warehouse in the years 2007 and 2008, a central heating unit was installed at company´s Management. This system captures all room temperatures and then electronically regulates the correct temperature for all heating systems (pumps, heaters, radiators and underfloor heating) throughout the Company complex. The central heating system management enables the targeted and effective use of available energy. With all heating systems in the enterprise solely controlled by these units, it was possible to do without additional gas heating.

A time management control within the system allows by-the-minute activation for each heating zone. Therfore, besides the usual daily operation, separate reductions are possible for night, weekend and holiday modes - and much more can be automatically controlled by precise programming of the system. In this way precisely as much heating power is consumed only as is necessary. The investment costs for the installation of central heating management hit 297,500 euros. However - especially in the heating extent that arises every day, can be explained by the introduction of central heating management can save a lot of heat energy, so that the system will pay for the medium term. The control of the new geothermal system was completely integrated into the central heating management. This extension means for a further investment of 17,850 euros.

In 2010, the company installed another heat pump system with 125 kW power made. This pump supplies the main camp area (approx. 5,000 m2). Also an adjacent museum received another heat pump system with 45 kW of power. The investment for both plants was 535,500 euros. All heat pump systems can be usefully integrated into the existing central heating management. With this modernization the comapny has implemented heating systems once again on the cutting edge of technology.

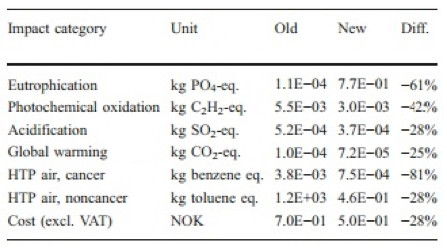

The life cycle inventory consequences of the two frameworks, old versus new, are appeared in Table 1. It was noticed that the reduction in emissions varies from about 25%, an effect purely caused by higher efficiency and reduced demand of upstream processes to 81 %, a result of significantly improved combustion conditions. The life cycle impact assessment results indicate the importance of the type of technology on an impact level.

Table 1. Results for delivering 1 kWh of heat from a wood stove using old and new technology.

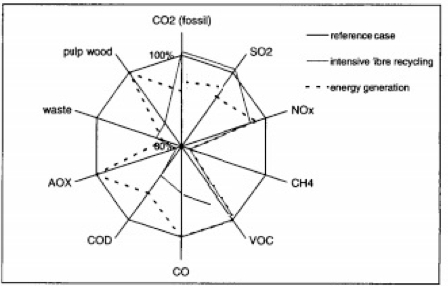

An intensive wood recycling is compared with combustion of natural gas for energy generation using an LCA. The present technology recovery rate is 57 %, and without any serious effect on quality. In the case 'energy generation' 38% is used for combined heat and power production, whereas the recovery rate is 49%. The results are shown in Fig. 3. Recycling results in less wood raw material (pulpwood from forestry) and lower emissions to water and air from wood harvesting and transport. Energy generation lowers the CO 2 and SO 2 emissions resulting from energy production. Recycling and energy production reduces the load on landfill sites and thus CH4, COD and NO. emissions are reduced.

Fig. 3: Comparison of recycling and energy generation – Old System x New System

According to Fisher (2005), the emissions reduction and resource protection potential of renewable energy systems could then partially be offset by a 'rebound effect', thus implying that environmental benefits achieved by a more benign technology are at least partly compensated, and sometimes overcompensated, by an increase in energy demand.

Installing renewable energy systems could also lead to a stimulated environmental consciousness and enhanced involvement in energy topics. This effect greatly depends on the specific form, timing and detail of feedback, and on the presence of other incentives, such as price incentives, importance of independence, and ecological motives.

Using biomass fuels provides substantial environmental benefits. The global warming concern, the decrease in easily exploitable oil reserves and the increase of oil use in many countries increase the interest in biofuels. From the LCA results it follows that for all renewable energy chains the inputs of finite energy resources and emissions of greenhouse gases are extremely low compared with the conventional system. The relevant environmental impacts of the renewable energy systems amount to a maximum of 25% of an expected future.

The results from the present life cycle assessment show that the new systems technology significantly improves the performance (28–80%) for all types of environmental impacts studied. As long as the wood is produced locally, the use phase is responsible for the majority of the impacts. Hence, the replacement of old technolgy with new machines significantly improves the environmental performance of old machines for heating. Although it considered the emissions of CO2 from combustion of biomass "climate neutral, " there are greenhouse gas emissions associated with the supply of wood, as well as emissions of methane in the combustion phase. Hence, wood-based heating also contributes to climate change. Given the significant improvement in changing to new machines, stronger policies encouraging the replacement of old machines could be introduced.

Lengthening the lifespan of wooden materials by recycling of wood waste is an important approach to combating global warming, because the longer use of wooden materials means longer storage of carbon fixed from carbon dioxide through photosynthesis.

Babić, M. J. et al. (2010). Analysis of the Electricity Production Potential in the Case of Retrofit of Steam Turbines in a District Heating Company, Thermal Science, 14, Suppl., pp. 27-40.

Barton, J.R., Dalley, D., Patel, V.S. (1996). Life cycle assessment for waste management. Waste Manage., 16 (1996), pp. 35–50.

Campbell, P.K., Beer. T, Batten, D. (2011). Life cycle assessment of biodiesel production from microalgae in ponds. Bioresour.Technol., 102, pp. 50–56.

Fischer C. (2005). Consumer behaviour and consumption patterns. In: Pehnt M, Schneider L, editors. Micro-cogeneration. Heidelberg: Springer.

Ghafghazi, S., Sowlati, T., Sokhansanj, S., Bi, X., Melin, S. (2011). (in press). Life cycle assessment of base-load heat sources for district heating system options. Int. J. Life Cycle Assess.

Hall, P. and Gifford, G. (2008). Bioenergy Options for New Zealand-a Situation Analysis of Biomass Resources and Conversion Technologies Scion, Energy Group, Rotorua, New Zealand.

J.R. Barton, D. Dalley, V.S. Patel (1996). Life cycle assessment for waste management. Waste Manag, 16, pp. 35–50.

Khan, A.A., Jonga, W.D., Jansens, P.J., Spliethoff, H. (2009). Biomass combustion in fluidized bed boilers: potential problems and remedies Fuel Process Technol, 90, pp. 21–50.

Obata. Y, Takeuchi. K, Furuta. Y., Kanayama, K (200%). Research on woods as sustainable industrial resources: evaluation of tactile warmth for woods and other materials. Energy, 30 (8), pp. 1317–1328.

Ries, F.J, Marshall, J.D, Brauer, M. (2009). Wood energy: The dangers of combustion; Science., 324 (2009), p. 1390-a.

Sathre, R., Gustavsson, L. (2006). Energy and carbon balances of wood cascade chains. ResConRec, 47 (2006), pp. 332–355

Werner, F., Taverna, R., Hofer, P, Richter, K. (2005). Carbon pool and substitution effects of an increased use of wood in buildings in Switzerland: first estimates. Ann For Sci, 62, pp. 889–902.

Werner, F., Richter, K. (2007). Wooden building products in comparative LCA. A literature Review Int. J. LCA, 12, pp. 470–479.

1. Mestre em Engenharia de Produção (UFSM). Universidade Federal de Santa Maria - UFSM castellanelli@bol.com.br