1. Introduction

The competitive and globalized market currently demands not only competitive strategies for the company which produces the end product, but for all the supply chain, from the development of the raw material to the end consumer. Therefore, competition is not defined any more inside an isolated company, but in the organization nets (company, suppliers, and retailers). The supply chain represents companies’ net through which the different products, processes and activities to produce value in the form of products and services that are commercialized.

Novaes (2004), Ahumada and Villalobos (2009) state that the supply chain is a sequence of value chains, each one corresponding to the union of the companies, which form a production system or a service aimed at transmitting the same value to all the chains. However, it is necessary to define the term value. To Womack and Jones (2004), value is determined by the desires of the end client in the chain. Value is only significant when it is defined in a specific product (a good or a service, and, very often, both simultaneously) which supplies the needs of the client with an affordable price and at the desired moment. The immediate needs of the shareholders and the financial mentality of the senior managers predominate over the daily realities of specifications and the value creation for the client.

Value is what clients are willing to pay for the product that the company offers them. Therefore, each individual establishes the value or the acquired service according to the benefit added by such product. Value may increase by means of the differentiation of services and products or only the advantage of a great productivity (PORTER, 1985).

Value has traditional definitions which often may not really define its meaning for a client. When suppliers or internal clients decide to rethink value, in general, they use simple formulas, such as low cost, broader range of products through customization, immediate delivery instead of an analyzing value as a whole and questioning old definitions in order to know what is really needed. Although the value generation frequently flows through many companies, each one of them tend to define value in a way which is more adequate to their own needs. When such definitions are gathered together, very often the addition does not bring a good result (WOMACK and JONES, 2004).

To Novaes (2004), the supply chain (SC) is formed by a sequence of value chains, according to the needs of each company which forms the system. The definition of value, set according to the needs of the end client of the SC, present the external information that moves out to a complex system, and the shareholder point of view, considering value as the profit earned in the chain companies, the internal actions of this complex system. Defining and analyzing value in a complex system such as a SC is a hard task, because the value conception is something subjective and varies to each organization, and even to each individual who come to manage and take part of the actions which add value in a SC. Therefore, the accomplishment of value in the SC consists on the link of the market (client’s value) and the operational activity of the company and its costs (the value for the shareholders). In order to exemplify this conception in a better way, the description of the value chain and the standards, forms and ways for the value-addition is important.

There is a confusion regarding which values are important for the Supply Chain Management and which are the views, forms and ways for its acquirement. The aim of this research is to systematize the conception of value at a SC by means of a bibliographical research targeting the evidence of the standards, forms and ways for different points of view (client/ shareholder).

2. Systemic approach and the complexity of the supply chain management

The conception of system is an integrated whole whose properties are not intrinsic, but they can be understood only in the view of the whole. A system is a group of interrelated elements which the observer considers as a more ample totality. (CAPRA, 1996; ENGELMANN 2002; IAROZINSKI NETO, LEITE, 2010).

The general theory of the systems was formulated by Bertalanffy (1975) with the intention of investing in the development of models (reality representations) and determining the general principles which may be applicable to systems of any nature. The models and systems shall be specific for their study objects and they should not be produced as analogies or migrations of conceptions between areas for practical solutions. The ample conception of a system presents classifications for its understanding, as well as the complexity levels of the interrelations of this system. (BOULDING, 1956; MORIN, 2002). The classification of a system to Morin (2002) may present three levels: simple, complicated and complex. One can easily understand simple systems; however, this classification of systems is not easy to do. The complicated systems, in order to be understood, may be reduced to simple systems without the destruction of their essence. The majority of the existing systems presents the complex classification and can only be understood in their whole by means of hierarchies.

The hierarchical classification of systems complexity by Boulding (1956) is made up by nine levels of difficulty, each one determined by the distinction of their own features, which are determined by their increasing level of complexity as systems: frameworks (static structures); clockworks (simple dynamic); thermostat (cybernetic control); cell (which is open and self-supporting); plant (division of functions and differentiation between genotype and phenotype); animal (mobility and theological behavior); human (self-conscience); social organization (communication); and transcendental (beyond human comprehension).

SC is a social complex system formed by people organized in different companies, with multiple inputs and outputs, and it has as its common target the profit making, reaching the value for clients and shareholders by means of the production and commercialization of a product or service. The classic approach of a social entrepreneurship, for Iarozinski Neto and Leite (2010), as well as the SC, is represented by the input of an object, or all of it, beyond the boundaries (information, raw material, etc.) and the transformation by means of a process. The activities of the SC are accomplished through a synchronization of the value transmission for the client and the optimization of the production processes through a reduction of the costs for the shareholders. The search for values in complex systems, such as a SC needs an analysis of different standards which execute and transmit value in the SC.

3. Value versus costs for companies in the supply chain: measuring values

The commercial success reached through the strategic thinking is reached in the costs advantage, or in the value advantage, or, ideally, through both together. This is simple as the competitor that profits more in any production area tends to be the one who produces at the lower costs, or the one who offers a product with a greater differential in the market (CHRISTOPHER, 1997). The strategies for value and for costs cannot be thought of separately, but as strategies that result in positions of costs that appeal in relation to the supplied benefits. The companies need to follow their costs, in a way to improve their economical work, intending to add value to their clients (FARIA e COSTA, 2007).

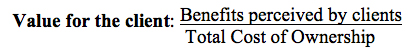

In order to analyze value, it is necessary to indicate what value is for the client and posterior for the shareholder in the SC, that is, to define value for client and lesser costs for the shareholders. According to Christopher and Gattorna (2005) the value for the client is generated when the perceptions of the apparent benefits in a settlement surpass the total cost of Ownership, which are expressed in the following formula:

(1)

(1)

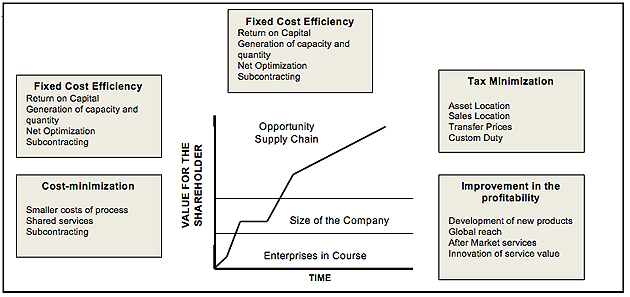

The total cost of ownership is associated to the physical costs (in the terms of power and time consumption) and money (CHRISTOPHER and GATTORNA, 2005). For the shareholders it is very important to know the costs composition and its structure for the production of a product. The value addition for the shareholder happens starting on the moment when this agent reaches an operational positive liquid result, minus the opportunity cost over the invested assets (FARIA and COSTA, 2007). The best decisions to add economical value to the SC for shareholders are illustrated in the figure 1.

Figure 1.

View of the shareholders in the supply chain. Source: adapted from Tyndall et al. (1999).

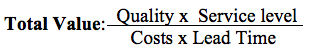

Adding value for the shareholders mean the costs reduction and the profit maximization. Value for shareholders is evidenced by means of a measurement of costs minimization, trading capital efficiency, fixed costs efficiency, tax minimization and profitability improvement (FARIA E COSTA, 2007; MARTINS ET AL., 2005; NEIGER, ROTARU AND CHURILO, 2009). However, in order for the SC to be efficient, structural changes are necessary or other changes which affect the charges and fees of the company. When these two standards are definitely optimized the value for the shareholder will be truly maximized. (TYNDALL et al., 1999). The value of the SC joins simultaneously the higher service to the client, while costs in the SC are minimized and the profit of the partners are maximized. However, Christopher and Towill (2000) present a new equation for the value measurement in order to range all the needs of clients and shareholders:

(2)

(2)

Quality is defined by the client’s trust and the service level definition is the benchmark of the competitors which are presented in the view of the needs of the end client: to the detriment of such standards, one has the costs and the lead time. The total value of the SC tends to be effective and efficient if the product or the service offered is different in relation to the competitors, with a quality within the desired schedule and with the smaller cost (KLIBI, MARTEL AND GUITOUNI, 2010; FLYNN, BAOFENG, AND ZHAO, 2010).

The philosophies Lean and Agile may be used by the SC management according to the value need also by the client or the shareholder. These are different, once the first case is determined by cost, why in the second philosophy the value is present in the availability or agility. The agile supply chains are forced to be commercially sensitive and, therefore, agile. This means that the definition of agility is different from the leaning thought. However Christopher and Towill (2000) present a evolution in the SC management, the “Leagile” trying to keep the SC lean, only with the processes which add value, and agile, in order to fulfill the needs of the end clients.

The standards and the philosophy are presented in the cost minimization, in the reliability culture among the members of the chain, for the transmission of the information regarding what value is for the final client in all the chain, and the integration of companies in order to transform the client information into a differentiated product and desired by the market. Between the equations 1 and 2, the standards to serve value for clients and shareholders are presented. In order for such standards to be accomplished in complex systems such as the SC, one has to find out the ways and procedures to execute them.

4. Forms and ways for adding value in the supply chain: links and interfaces

Forms and Ways are main elements of the value activities that lead the chain to have a competitive advantage, but they are not essential activities, as the standards are. The forms and ways may or not be used in the SC management. However, the value chain is not a group of independent activities, but an interdependent system of activities. The interlinking between value activities are formed by links, which reflect the relationships inside the company or outside it, and in the interfaces correspondent to the information exchange mechanism and products which will be conducted within the chain.

The order processing system existing in each element and each link in the SC should be critically examined for the identification of the value they add and the costs they produce. In the context, “value” regards the value perceived by the client, meaning a benefit which will contribute for the utility of the product and the advantage in the clients’ view and, consequently in their will to pay. (CHRISTOPHER, 1997; CRICELLI, GRIMALDI E GHIRON, 2010). The companies which desire to increase the value for their clients shall measure the sacrifices that the clients undergo when they order a product or a service. The Whole of the logistics management goes beyond the organization boundaries in order to include suppliers and clients, their links and interfaces. The logistics activities may be optimized in all the SC, minimizing resources and consequently costs, especially the financial costs. All the logistic values presented are necessary for the SC in their links and interfaces.

The value addition in the SC has in its links (company, supplier), for McCormack, Ladeira, Oliveira (2008) and Klibi, Martel and Guitouni (2010) the forms and ways for the capacity, quality, flexibility, customization, service speed and also are values for the SC. However, for the best satisfaction and liability of the end client, the SC has the forms and ways for trust and cooperation in the links, as essential for the value acquisition. The challenge consists in systematizing value in the SC in both versions of end client and shareholder, standards, philosophy (Lean and Agile), forms and ways. For this set of discussions, the research presents a methodology in a frequency index used to punctuate the importance of actions which add value in the SC management.

5. Classification of the Research

The nature of this research is applied because it produces means of managing a SC in the search for value for clients and shareholders. The approach of the problem is characterized by Markoni and Lakatos (2009) as qualitative, because it does not use statistical standards in order to analyze or qualify them. On the point of view of the objectives, the research is exploratory aiming at providing a broader familiarity and explicit them. The procedures were accomplished by means of a bibliographical research which consisted mainly of books and periodicals. The advantage of the bibliographical research for Gil (2009) is based in allowing the investigator to cover a range of phenomena much broader than the one which would be researched directly. Researching diverse situations which can add value in the SC becomes something broad and comprehensive to be researched. The approach method was inductive, based on the generalization of common features in a certain number of cases, observed until now, and applied to all the occurrences of similar facts which may be verified in the future.

6. Collection and treatment of data

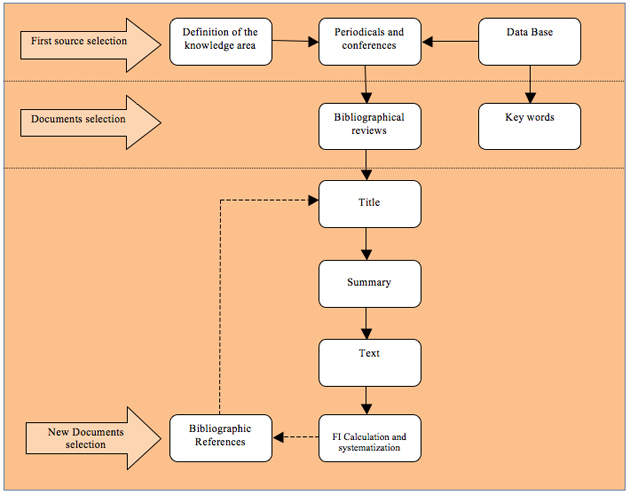

The data collection of the present research was accomplished in periodicals of ten platforms (ACM Digital Library, ACS Journals Search, Emerald Fulltext (Emerald), IEEE Xplore, IOPscience (Institute of Physics IOP), Nature (NPG); Science (AAAS), Web of Science,Scopus, ScienceDirect (Elsevier) e SpringerLink (MetaPress)), pertaining to the periodicals portal of the CAPES (Coordination for the Improvement of Higher Level -or Education- Personnel) and of the data base Scientific Electronic Library Online (SCIELO). The searches in such data bases were made with the following key words: supply chain, logistics, costs, value and client, in the time interval 2000 to 2010. These articles were interpreted in their function of systematizing the standards, forms and ways approached to add value to the SC, as the scheme in the Figure 2.

Figure 2

Bibliographic Research Method used. Source: Tezza (2010).

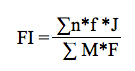

The treatment used to classify the actions pointed by the authors that add value to the SC such as standards, forms and ways was the Frequency Index. This method consists on classifying the important words in a determined topic by the frequency index in which it is presented as titles, keywords and conclusions. Where the frequency index (FI) is calculated:

When the relationship of the FI is greater than > = 0;

(3)

(3)

Where:

- n: action which adds value to be classified.

- f: amount in which these actions appear in the articles surveyed.

- M: all actions found out in the articles.

- F: amount in which all actions happens.

- J: the innovation factor.

The innovation factor is calculated according to the year in which the articles were published, according to chart 1.

Chart 1 – The innovation factor

Year |

J |

2009/2010 |

100% |

2007/2008 |

80% |

2005/2006 |

60% |

2003/2004 |

40% |

2000 /2002 |

20% |

Source: the authors.

After identification of standards, forms and ways, these were systematized according to the basic representation of the production systems.

7. Systematization of views, standards, forms and ways of value in the supply chain management

In the bibliographic research in the ten databases, 100 articles were found out having as one of their key words supply chain, value, logistics, client and costs. After reading the summaries, forty articles approaching the topic of the purposed aim were identified. Thus the stage of mapping and analysis to diagnose which were the main actions presented as value addition in the SC starting on the views of client and shareholder.

The actions which presented a frequency index equal or superior to 10 % were classified as standards necessary for the consolidation of clients’ and shareholders’ values in the SC. The forms and ways of value in the SC were diagnosed for frequency indexes under 10%, and these were important, but not essential to the effectiveness and efficiency of a complex system such as the SC. The Classification of the value activities in the SC is presented in chart 2.

Chart 2 – Classification of standards, forms and ways of value addition to the supply chain

Action |

Frequency |

Inovation factor |

FI |

Classification |

Information Technology |

26 |

0,68 |

0,14 |

Standards |

Integration |

19 |

0,6 |

0,09 |

Standards |

Costs |

19 |

0,5 |

0,08 |

Standards |

Culture |

11 |

0,95 |

0,08 |

Standards |

Sustainability |

8 |

1 |

0,06 |

Standards |

Flexibility |

13 |

0,6 |

0,06 |

Forms and ways |

Agility |

8 |

0,71 |

0,05 |

Forms and ways |

Knowledge |

6 |

0,9 |

0,04 |

Forms and ways |

Quality |

5 |

0,6 |

0,02 |

Forms and ways |

Cooperation |

3 |

0,9 |

0,02 |

Forms and ways |

Governance |

3 |

0,9 |

0,02 |

Forms and ways |

Environment |

2 |

1 |

0,02 |

Forms and ways |

Synchronization |

2 |

0,69 |

0,01 |

Forms and ways |

Reliability |

1 |

0,74 |

0,01 |

Forms and ways |

Source: the authors

The high innovation factor was set on actions of the SC regarding knowledge, environment, and sustainability, which presented articles only since the years 2009 and 2010. However, the profile of a sustainable chain had the amount of quotations to be classified as a standard for the innovation of value in a SC. The information technology and integration presented researches since 2000. Those are already recognized as traditional Standards and necessary in a chain which pursuits the value addition. The integration and the information technology are Standards renown in the hierarchy of Complexity by Bouling (1956), as systems of social organizations which aim at the communication between the systems for their evolution.

The standard cost was highlighted in the researches regarding value addition in a SC, but no one of the articles in the list presented the costs of benefits for the client through market researches, for example. (HAMMERVOLL, 2009). The culture was a standard that emerged in 2007, together with the perception of the knowledge which flows within a SC and the governance in which the chain is framed. However, the items knowledge and governance were classified as forms and ways of adding value. The flexibility, the speed and the synchronization in the researches about value in the SC were classified as forms and ways. Forms and views are activities necessary for attaining a standard in a SC, the integration.

Governance was classified as form and views, with only three articles, taking into account the actions to manage a SC, something important to be researched. However, a chain without efficient governance tends to be a group of companies without a direction within the market. The systematization of authors, standards, forms and ways, and views of the researches reviewed are structured in a general way in table 1, aimed at a better view of the evolution in the quest for adding value to a SC.

Table 1: Structure of the value in the Supply Chain.

Author |

Standards |

Forms and Ways |

View |

Christopher and Towill (2000); Cachon and Fisher (2000); Horvath (2001); Rodan and Miyake (2004); Reiner (2005); Sherer (2005); Sridharan, Caines and Patterson (2005); Guarnieri et al.(2006); Tolim (2006); Bandeira and Macada (2008); Ahumada and Villalobos (2009); Ketzenberg (2009); Taylor and Fearne (2009) and Costa and Maçada (2009). |

Information Technonolgy (IT) |

Speed, Synchronization and flexibility |

Shareholder |

Al-Mudimigh, Zairi and Ahmed (2004); Seuring (2006); Brun and Castelli (2008); Lanier,Wempeb, Zacharia(2010);Cricelli,Grimaldi and Ghiron (2010); Klibi, Martel and Guitouni (2010) and Saura, Francés and Blasco (2010). |

Integration |

ynchronization, reliability, knowledge and velocity |

End Client and shareholder |

Phillips and Smyth (2004); Christopher and Gattorna (2005); Martins et al. (2005); Ketchen and Hult (2007); Neiger, Rotaru and Churilo (2009); Flynn, Baofeng, and Zhao (2010) and Nagurney (2010); Ziya and Barthold (2010). |

Costs |

Synchronization, speed and flexibility |

Shareholder |

Ketchen, Rebarick, Hult and Meyer (2007); Hammervoll (2009); Cheung, Myers and Mentzer (2010); and Saranga and Moser(2010). |

Culture |

Cooperation, reliability, knowledge and governance |

End Client and shareholder |

Aquino et al. (2009); Salama, Luzzatto and Towill (2009); Kayakutlu and Büyüközkan (2010) and Pullman and Dillard (2010). |

Sustainability |

Knowledge, enviroment and governance |

End Client and shareholder |

Source: the authors.

From 2007 on, the Standards of technology, information and costs were discussed less frequently, opening way to new value conceptions in the SC. These new conceptions directed to the relationship between companies and clients, such as: culture, integration and sustainability were not only made up of basic information, but knowledge of the chain supporters. The years 2002 and 2003 did not present researches on value in the SC, a factor which produced doubts and no clarification about the reason why there were no articles published on the topic in these years. Standards did not comprehend just the shareholders’ view, but also the view of the final client. Only the Standards are not enough to support the systematization of the chain. Besides those pillars, there is the need of viewing the forms and ways and transforming the SC in a value chain.

The forms and views were classified according to their link for the execution of the standards. The information Technology as value addition has to have speed forms and ways, in order for the information to reach the links and the interfaces of the chain for the shareholders in their SC. Therefore, synchronization and flexibility are presented starting on this information for the execution and the production of each component of the product and service existing in the chain. The standard culture present forms and ways for adding the values of cooperation and reliability, which are synonyms of quality in the SC, the knowledge and the governance which manages all the activities executed and represent the mirror of the culture in which this chain is included. Sustainability is an innovative standard in the SC that presents governance, knowledge and the environment as forms and ways for its execution. This structure is determined as a consequence of the environmental and social culture of the researches performed in the last two years.

The standards, forms and ways were classified also according to the two views of value presented in the theoretical references. The view o the end client is presented as a value in the standards culture and sustainability. Culture is directed to the service of the client’s desires in all the chain, and the financial view, as a consequence of this desire fulfilled, is an essential standard in the supply chain. Sustainability is a strong trend currently. There is no way of foreseeing its importance as a similar standard to a culture in a SC, as it will depend on the maintenance of the value conception for the end client. The forms and ways of the end client’s view are the environmental management, reliability, cooperation and mainly governance. The view of the shareholder focused on the standards of costs reduction by means of integration, information technology and forms and ways of speed, synchronization and flexibility of the actions which may add value to the CS. (KETZENBERG,2009; CHRISTOPHER, GATTORNA, 2009).

In the international databases there was no Brazilian article which approached the topic of value in the SC. Thus, after the search of articles about value in the SC in international databases, the Brazilian database SCIELO, illustrated in the table 2 was the chosen database for the research. There, seven articles were found out, and the standards which motivated the search of value for the shareholder and the client within a SC were pointed out.

Table 2. The Brazilian publications found out for the value in the supply chain.

Year |

Title |

Periodical |

Standards |

View |

Rodan and Miyake (2004) |

Forecast changes in the motor industry: structure of the processes of decision making and processing of the information. |

Gestão e Produção (Management and production) |

Information technology |

Shareholder |

Costa and Maçada (2009) |

Management of the inter organizational information in the motor supply chain |

ERA |

Information Technology |

Shareholder |

Martins et al. (2005) |

Strategic decisions in the logistics of the agribusiness: costs compensation, transportation and storage for the soy bean production in Paraná State |

RAC |

Transportation Costs |

Shareholder |

Guarnieri et al. (2006) |

WMS -Warehouse Management System: adaptation proposed for the management of the reversed logistics |

Produção (Production) |

Information Technology |

Shareholder |

Bandeira and Maçada (2008) |

Information Technology in the supply chain management: the case of gases industry |

(Production) |

Information Technology |

Shareholder |

Aquino et al. (2009) |

The net organization of the recycling materials collectors in the reversed production chain of post-consumption in the Great Florianópolis: an alternative for value addiction |

Gestão e Produção (management and production) |

Sustainability focused on the environmental management |

End Client |

Oliveira and Leite (2010) |

Analytic model to support the configuration and integration in the supply chain |

Gestão e Produção (management and production) |

Integration |

Shareholder and End Client |

Source: the authors.

The articles found out in the research of the database of Brazilian periodicals had research standards, mainly for the information as the greatest value in a SC, but none of them approached information about what is value for the client. The Standard integration was placed as a factor which had as its objective the information technology, however, integration is not only attained this way in a SC. The costs as value were cited by an article, but not in the SC management. The focus only was directed towards the process, the logistics and specifically in the act of supply and goods transportation. An article is worth mentioning, about the net organization by the recycling material collectors in the reversed production chain of post-consumption of the region of the Great Florianopolis: an alternative for value addition, which viewed as value the environmental issue in products returned for the clients, a value pointed by the research as a form and a way of adding value.

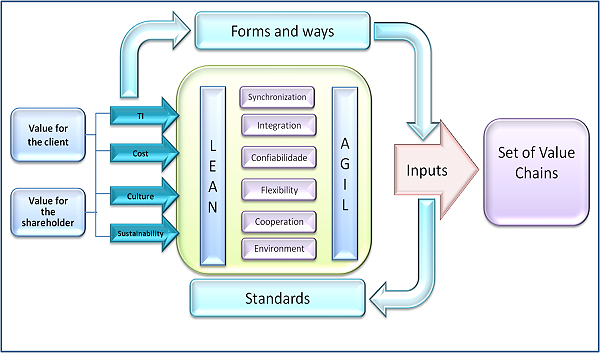

Figure 3.

Value Systematization in the SC. Source: the authors.

In the chart 2 and tables 1 and 2, one can view the aim of the research in systematizing value in the SC in the different views. The standards and ways are contemplated and structured in its whole in figure 3. The basic conception equally structured in a production system, the input of information in the chain of value views for the client and the shareholder, the systematization of standards, forms and views found out in the research bibliographic research according to the frequency index method. The philosophies Lean and Agile are present in the table above, and they present new management culture for activities which add value for the SC.

Lean and Agile are contextualized philosophies by Christopher and Towill (2000). The first determines the elimination of wasting and leans the chain activities. Agile consists on the agility for the service of volatile market demands. Thus, the systematization consists in determining value in a chain which serves to two distinct views through standards, forms and ways with the Lean and Agile conceptions. Therefore, the systematized SC has as its output its transformation into a value chain.

8. Final Considerations

The frequency index method allowed the classification, by means of analysis in periodicals, of the standards for value addition in the supply chain management and its forms and ways. The systematization of value management in the SC was presented by the input of two views (clients/ shareholders) and the output of a supply chain.

The conception of value in the SC, after this system research, was characterized by the grouping of market competition strategies and minimization of costs in the production chain of a product. In order to reach this value, the SC has the need of transforming in information what is value for the end client and how to acquire it in its lesser cost for the shareholders.

Thus, the systematization of value in the SC through the bibliographical analysis pointed out to the evolution in the standards research which adds value in the SC, its forms and ways and the view to be attained. This systematization follows the importance of information and the knowledge, evidences the standard, the sustainability as value addition, mainly for the view of the end client. Such systematization displayed a way of management for the value addition in a SC, and also showed actions that lack more research about the supply chain.

In Brazil there are breaches in the research about value in the SC presented by the SCIELO database. This reality happens so because the Brazilian managers don’t have the competition view between the nets of companies, in all the SC that the product follows. They only have the view of the company which produces the final product. Thus, there is a long way to the accomplishment of researches to improve the management in the SC by means of views of values for the client and shareholder in our country.

The results presented regarding the lack of research in the value chain in Brazil and the hypothesis of systematization proposed by this paper emphasize the need for future researches regarding the application of this systematization to analyze its behavior in a SC; the alignment of the value standards in a SC for market and costs; analyze the importance of the environmental value in the SC for the market; the analysis of the logistical costs in companies which have as a strategy the value for their productivity and value for differentiation, besides comparing the governance on the SC behavior focusing value.

9. References

AL-MUDIMIGH, A. S.; ZAIRI, M.; AHMED, A. M. (2004). “Extending the concept of supply chain: the effective management of value chains”. International Journal Production Economics, v. 8, n.7, p. 309–320,.

AHUMADA, O.; VILLALOBOS, R.(2009). “Application of planning models in the agri-food supply chain: A review”. European Journal of Operational Research, v.19, nº 5, p.1-20.

AQUINO, I. F.; CASTILHO, A. B.; PIRES, T. S. (2010).”A organização em rede dos catadores de materiais recicláveis na cadeia produtiva reversa de pós-consumo da região da grande Florianópolis: uma alternativa de agregação de valor”. Revista Gestão e Produção, v. 16, n. 1, p. 15-16.

BANDEIRA, R. A.; MAÇADA, A. C.(2008). “Tecnologia da informação na gestão da cadeia de suprimentos: o caso da indústria gases”. Revista Produção, v.18, n.2, pp. 287-301.

BERTALANFFY, L. (1975). Teoria geral dos sistemas. 2ª ed. Petrópolis: Vozes.

BOULDING, K. E. (1956). “General systems theory: the skeleton of science”. Management science, v. 2, n. 3, p. 197-208.

BRUN, A.; CASTELLI, C. (2008).” Supply chain strategy in the fashion industry: Developing a portfolio model depending on product, retail channel and brand". International Journal Production Economics, v. 11, n.6, p 169–181.

CACHON, G.P.; FISHER, M. (2000). “Supply Chain Inventory Management and the Value of Shared Information”. Management Science, V. 46, No. 8, pp. 1032–1048.

CAPRA, F.(1996). A teia da vida. São Paulo: Cultrix.

CHEUNG, M.; MYERS, M.B.; MENTZER, J.T.(2010). “Does relationship learning lead to relationship value? A cross-national supply chain investigation”. Journal of Operations Management, v. 14, n.1, p. 1-16.

CHRISTOPHER, M. (1997). Logística e gerenciamento da cadeia de suprimentos: estratégias para a redução de custo e melhoria de serviços. São Paulo: Pioneira.

CHRISTOPHER, M.; GATTORNA, J. (2005). “Supply chain cost management and value-based pricing”. Industrial Marketing Management, v. 34, n. 2, p. 115-121.

CHRISTOPHER, M.; TOWILL, D.R. (2000). “Supply Chain Migration from Lean Functional to Agile and Customised”. Supply Chain Management: An International Journal, v. 5, n.4, p.206-213.

COSTA, J. C.; MAÇADA, A.C.G. (2009). “Gestão da informação interorganizacional na cadeia de suprimentos automotive”. Revista de Administração Eletrônica, v. 8, n. 2, 2009.

CRICELLI, L.; GRIMALDI, M.; GHIRON, N. T. (2010. The competition among mobile network operators in the telecommunication supply chain. International Journal Production Economics, v. 15, n.6, p.6-15.

ENGELMANN, A. (2002) “A psicologia da gestalt e a ciência empírica contemporânea”. Psicologia: teoria e pesquisa, v. 18, n. 1, p. 1-16.

FARIA, A. C.; COSTA, M.F.G. (2007). Gestão de custos logísticos. São Paulo: Atlas.

FLYNN, B. BAOFENG, H.; ZHAO. C. (2010). “The impact of supply chain integration on performance: a contingency and configuration approach”. Journal of Operations Management. v. 28, n.6, p. 58–71.

GIL, A.C. (2009). Como elaborar projetos de pesquisa. 4ª Edição. São Paulo: Atlas.

GUARNIERI, P; CHRUSCIACK, D.; OLIVEIRA, I.; HATAKEYAMA, K.; SCANDELARI, L. (2006). “WMS– Warehouse Management System: adaptação proposta para o gerenciamento da logística reversa”. Revista Produção, v. 16, n. 1, p. 126-139.

HAMMERVOLL, T. (2009). “Value creation in supply chain relationships: a critique of governance value analysis”. European Journal of Marketing, v. 43, n. 5/6, p. 630-639.

HORVATH, L. (2001). “Collaboration: the key to value creation in supply chain management”. Supply Chain Management: An International Journal, v.6, n.5, p. 205–207.

IAROZINSKI NETO, A.; LEITE, M. S. (2010). “A abordagem sistêmica na pesquisa em Engenharia de Produção”. Revista Produção, v. 20, n. 1, p.1-14.

KAYAKUTLU, G.; BÜYÜKÖZKAN, G. (2010). “Effective supply value chain based on competence success”. Supply Chain Management: An International Journal, v.15, n.2, p. 129–138.

KETCHEN, D.; G. HULT, T. (2007). “Bridging organization theory and supply chain management: The case of best value supply chains”. Journal of Operations Management, v. 25, p. 573–580.

KETCHEN, D.; REBARICK, G. HULT, T.; MEYER, D. (2008). “Does relationship learning lead to relationship value? A cross-national supply chain investigation”. Business Horizons. V. 5, n.1, p.235-243.

KETZENBERG, M.(2009). “The value of information in a capacitated closed loop supply chain”. European Journal of Operational Research, v.19, n.8, p. 491-503.

KLIBI, W.; MARTEL, A.; GUITOUNI, A.(2010). “The design of robust value-creating supply chain networks: A critical review”. European Journal of Operational Research. v. 20, n.3, p. 283–293.

LANIER, D.; WEMPEB, W.; ZACHARIA, Z.(2010). “Concentrated supply chain membership and financial performance: Chain- and firm-level perspectives”. Journal of Operations Management, v. 28, n.4, p. 58–71.

MARTINS, R. S.; REBECHI, D.; PRATI, C. A.; CONTE, H.(2005).” Decisões estratégicas na logística do agronegócio: compensação de custos transporte-armazenagem para a soja no estado do Paraná”. Revista Administração Contemporânea. [online], v.9, n.1, p. 53-78.

MCCORMACK, K.; LADEIRA,M.B.; OLIVEIRA, M.P. (2008). “Supply chain maturity and performance in Brazil”. Supply Chain Management: An International Journal, v. 13, n.4, p.272-282.

MORIN, E. Educação e complexidade: os sete saberes e outros ensaios. São Paulo: Cortez, 2002.

NAGURNEY, A.(2010). “Optimal supply chain network design and redesign at minimal total cost and with demand satisfaction”. International Journal Production Economics, v. 15, n.6, p. 6-18.

NEIGER, D.; ROTARU, K.; CHURILOV, L. (2002). “Supply chain risk identification with value-focused process engineering”. Journal of Operations Management, v.27, p.154–168.

NOVAES, A.G. (2004). Logística e gerenciamento da cadeia de distribuição: estratégia, operação. Rio de Janeiro: Campus.

OLIVEIRA, J.B; LEITE, M.S.A. (2010). “Modelo analítico de suporte à configuração e integração na cadeia de suprimentos”. Gestão e Produção, v. 17, n.3,p. 447-463.

PHILLIPS, P.; SMYTH, S. (2004). “Managing the value of new-trait varieties in the canola supply chain in Canada”. Supply Chain Management: An International Journal, v. 9, n.4, p. 313-322.

PORTER, M. E.(1975). Competitive advantage: creating and sustaining competitive performance. New York : Free Press, 1985.

PULLMAN, M.E.; DILLARD, J.(2010).” Values based supply chain management and emergent organizational structures”. International Journal of Operations & Production Management, v. 30, n.7, p. 744-771.

REINER, G. (2005). “Customer-oriented improvement and evaluation of supply chain processes supported by simulation models”. International Journal Production Economics, v. 9, n.6, p.381–395.

RODAN, F.; MIYAKE, D. I. (2004). “Mudanças de forecast na indústria automobilística: iniciativas para a estruturação dos processos de tomada de decisão e processamento da informação”. Revista Gestão e Produção, v. 11, n. 3, p. 413-427.

SAURA, I.G; FRANCÉS, D.S; BLASCO, M.F. (2010). “Antecedents and consequences of logistics value: And empirical investigation in the Spanish market”. Industrial Marketing Management, v. 36, n.1, p. 493-506.

SALAMA, K. F.; LUZZATTO, D.; SIANESI, A.; TOWILL, D. (2009). “The value of auditing supply chains”. International Journal Production Economics, v. 11, n. 9, p. 34–45.

SARANGA, S.; MOSER, R. (2010). “Performance evaluation of purchasing and supply management using value chain DEA approach”. European Journal of Operational Research, v. 20, n.7, p.197–205.

SEURING, S. A.(2006). “Supply chain controlling: summarizing recent developments in German literature”. Supply Chain Management: An International Journal, v.11, n.1, p. 10–14.

SHERER, S. A.(2005). “From supply chain management to value network advocacy: implications for e-supply chains”. Supply Chain Management: An International Journal, v. 10, n.2, p. 77-83.

TAYLOR, D. H.; FEARNE, A.(2009). “Demand management in fresh food value chains: a framework for analysis and improvement”. Supply Chain Management: An International Journal. v.14, n.5, p. 379–392.

TEZZA, R.; BORNIA, A.C.; VEY, I.H. (2010). “Sistemas de medição de desempenho: uma revisão e classificação da literatura.” Gestão e Produção, v. 17, n.1, p.75-93.

TOLIM, B. (2006). “On the Value of Mitigation and Contingency Strategies for Managing Supply Chain Disruption Risks”. Management Science, v. 52, n. 5,pp. 639–657.

WOMACK, J.P.; JONES, D. T. (2004). A mentalidade enxuta nas empresas Lean Thinking: elimine o desperdício e crie riqueza. Rio de Janeiro: Elsevier.

ZIYA, E.; BARTHOLD, J. (2010). “Centralizing Inventory in Supply Chains by Using Shapley Value to Allocate the Profits”. Manufacturing & Service Operations Management, v.4, n.24, p. 1-17.